views

Deciding What Type of Metallurgist to Be

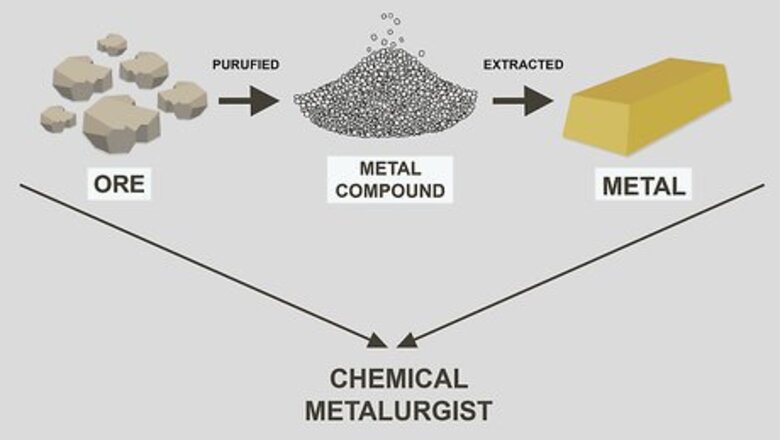

Be a chemical metallurgist if you want to deal with extracting metal from ore. Chemical metallurgists develop and monitor processes for extracting and manufacturing usable metals. They also study metal corrosion and fatigue. To become a chemical metallurgist, you should have a strong interest in chemistry. As a chemical metallurgist, you might work on developing ways to make metals stronger, improving extraction and manufacturing processes, creating recycling strategies, and testing metals to make sure they meet safety and quality standards.

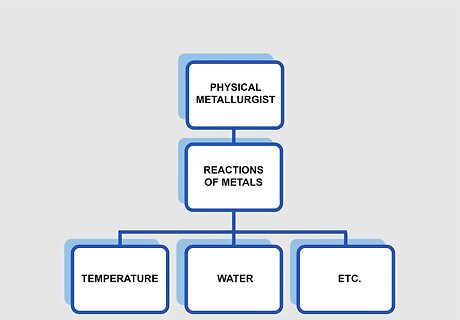

Be a physical metallurgist if you want to study the properties of metal, including how it reacts to stress. Physical metallurgists study the physics of metals and how they change under stress, such as changes in temperature. They analyse the structure and composition of metals and how they react to different processes, such as being placed under heavy weight. If you are interested in physics, then physical metallurgy could be a good choice for you. As a physical metallurgist, your job duties might include investigating accidents that could be due to metallurgical failure, running process and product development trials, and writing reports on tests and investigations.

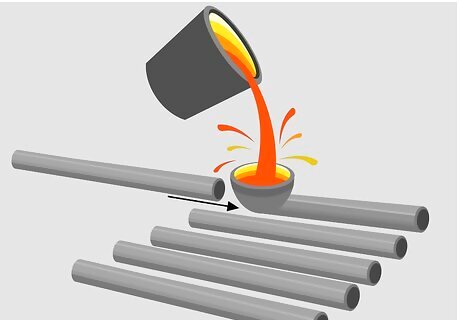

Become a process metallurgist if you want to shape and join metals. Process metallurgists develop and produce metal parts and prototypes. They control the shaping processes of metals, such as casting, and join metals together by welding and soldering. Being a process metallurgist could be a good field for you if you want to physically produce usable metal parts. Physical metallurgists produce everything from small parts used in medical science, to huge parts used in construction. As a process metallurgist, your job duties could include interpreting design drawings, selecting the best metal to use, making recommendations about designs, and creating metal products to precise specifications.

Getting the Right Education

Get an undergraduate degree in materials science or engineering. Metallurgists need to have at least a bachelor’s degree in order to work in the field. You will need to take a heavy load of science, mathematics, and technology courses to get the right degree. Some types of courses that you will need to take to become a metallurgist include: materials science, materials engineering, chemical engineering, metallurgy, physics, mechanical engineering, calculus, computer science, information technology, and more.

Do an internship at a company that specializes in materials engineering. Many universities partner with local companies, such as engineering firms or auto manufacturing plants, to provide internship opportunities to their students. Internships will give you hands-on experience and allow you to network within the industry to potentially get a job right upon graduation. Try to find a degree program at an engineering school or university that combines laboratory work and professional experience with the academic courses to improve your job prospects upon graduation.

Pursue a graduate degree if you want to work in research and development. Continuing your education to get a master’s degree in materials engineering or science will open up more job opportunities in the research and development areas of metallurgy. It will also improve your overall professional knowledge in the field. Some universities offer combined programs through which you can get both an undergraduate and graduate degree in the field.

Finding a Metallurgy Job

Join a professional association for metallurgists to network in the field. The most well-known is the ASM International which is the world’s biggest materials information society. Join an association such as the ASM to connect to a global network of metallurgy peers and organizations. Other metallurgy associations include: the Society for Mining, Metallurgy and Exploration, and the American Foundry Society. Professional organizations typically require membership dues, but some employers will reimburse these, so it is worth it if it helps you find a good job in metallurgy. The ASM also offers certification and licensing for metallurgy professionals that can help add to your professional credentials.

Look for jobs at companies involved in the manufacturing of metals. These types of companies include steel manufacturers, mining companies, refineries, foundries, copper manufacturers, and producers of precious metals. Search online or through professional organizations for jobs at these kinds of companies. Keep in mind that in many countries the metal manufacturing industries are focused heavily in certain areas, so you may need to focus your job search in these areas and be open to relocation.

Apply to jobs with specialist consultancies as an alternative to manufacturers. There are many materials engineering consulting companies that offer different types of metallurgical consulting services. This is an especially good option if you want to be a physical metallurgist. Consultancy companies offer consultation on things like: materials selection, cost reduction, failure analysis, manufacturing process development, supplier evaluation, and research and development.

Comments

0 comment