views

Measuring the Gap

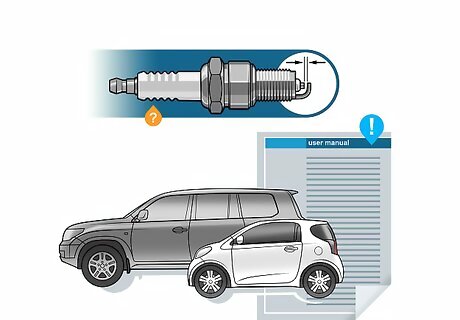

Learn your vehicle's gap specifications. Whether you're shopping for new plugs, you just bought new plugs that you want to check before installing, or you want to check the function of your current set of spark plugs, you need to learn the appropriate gap between the two electrodes on the end of each plug. Each vehicle's measurement will be different, though most are generally somewhere between 0.028-.06 inch (0.15 cm). You can either look in your owner's manual or go to the auto parts store and have them look it up for you. Modified engines require smaller gap settings to account for the amount of power you're putting through the engine. General rule of thumb: the more power, the smaller the gap.

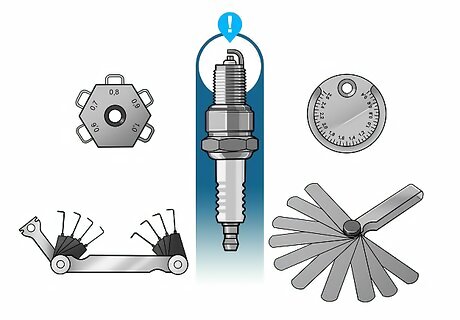

Select an appropriate gap tool. There are several varieties of tools used to measure the gaps of spark plugs, some of which are more appropriate for more modern plugs, which sometimes feature delicate precious metals. Most measuring tools will also feature a flat edge typically used for bending the bottom electrode on the spark plug to adjust the gap slightly. A coin-style gap measure is usually the cheapest option, and works by running the edge of the "coin" through the gap until you reach a point where it stops. The edge is marked like a ruler, designating the thickness of the edge at that point. This is a good tool for older plugs you want to check the efficacy of, but can also inadvertently widen the gaps as you use it. A wire coin gap works essentially the same way as the regular coin-style gap, but features different wire measures of varying lengths on the edge around the coin. A blade-style feeler gauge is an effective and versatile tool. Built like a pocket-knife, this gauge features different blades of varying widths, some with wire on the end and some without, placed in the gap to check the spacing of the electrodes. You can also use multiple blades to measure larger gaps. These are effective to use while adjusting.

Clean the spark plug. If you've just pulled it out of the box, it should be in pretty good shape, but if you're checking a plug that you've been using in your car it's a good idea to clean it off a little with a clean cloth. Spark plugs can build up some whitish soot on the contact points, so you'll want to make sure they're somewhat clean to get the most accurate reading. You can use a little bit of quick-drying (90%) alcohol on the contact points to clean them off if they're especially dirty. Lots of build-up or any blackening on the contact points might be a sign of a plug that's outlasted its prime, however. If they're especially dirty, you might consider buying new ones. There's a special tool designed for cleaning spark plug—think of it as a sand-filled pouch that's attached to an air compressor. It cleans the electrode of the spark plug by sandblasting it.

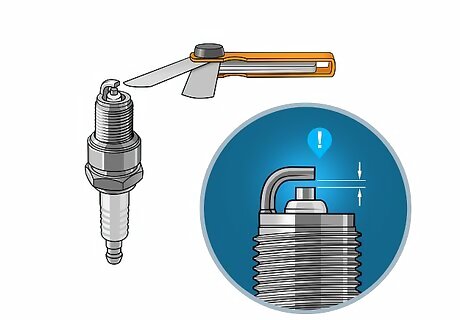

Measure the gap by passing the tool through the electrodes. Place the appropriate blade or wire on your gap tool between the electrode tips of the plug, or pass the coin through the electrodes to determine the measurement.

Adjusting the Gap

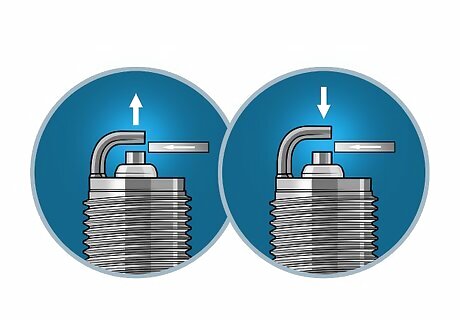

Determine if the gap needs adjusting. If the tool passes through the gap without touching the electrodes at the appropriate measure, your gap is too wide. If you can't fit it between the electrodes, the gap is too small and needs to be widened some. If it fits closely to the specified measurement, you're safe to install the spark plug. Most spark plugs and iridium plugs manufactured today don't need to be gapped prior to installing them. If you've got a custom modified engine, though, you might be interested in checking or installing plugs at a different spacing. Adjust them accordingly.

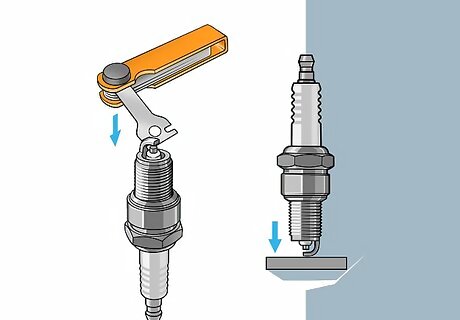

Use the tool to adjust the bottom electrode. When you hold the spark plug with the electrodes facing the floor, you'll want to bend the bottom one very gently either in toward the other electrode if you want to narrow the gap, or out, if you want to increase the gap slightly. Never bend more than a few (.02) fractions of an inch. It won't take much pressure, so be very careful. Spark plugs can be quite delicate, and any fracturing can cause misfires. If you're having trouble using the tool to adjust the gap, consider bending it in using a flat surface like a table to apply some very gentle pressure on the electrode to adjust it.

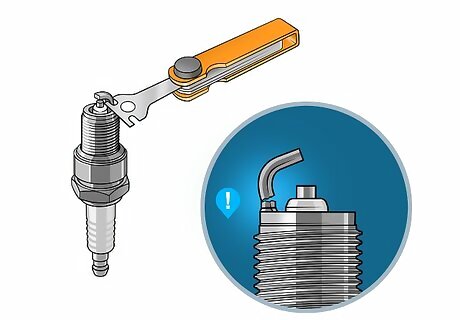

Re-measure the gap and adjust accordingly. Be very careful not to contact the electrode in the center of the plug and damage the core. If it breaks or shorts you'll need to toss it and buy a new one.

Be very gentle. Snapping off the electrode will waste your efforts, and it doesn't take much to do so. Use only a small amount of pressure to bend the electrode and only bend it a little bit.

Comments

0 comment