views

- Install injectable insulation foam by drilling holes in your drywall and spraying the expandable foam inside.

- You can also hire a contractor to install blanket or cellulose insulation inside finished walls.

- If you’re only insulating a room or two, it’s probably more efficient to remove the drywall and use standard spray foam.

Spray Foam DIY Insulation

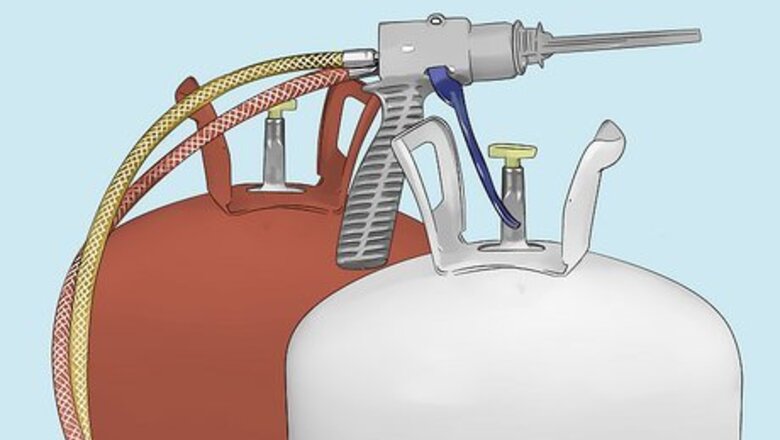

Choose an injection foam spray kit that meets your needs. Injection foam insulation expands inside of the wall to insulate it. This process is known as “drill and fill” retrofitting, and it’s basically your only option so far as DIY insulation options go. These kits contain everything you need to install the foam itself. Reach out to a manufacturer to schedule a delivery. One of the most popular options out there is the Tiger Foam spray kit. As a note, you 100% have to use “injection foam.” The normal polyurethane foam that doesn’t expand can not be applied to finished walls. DAP offers a Touch ‘n’ Foam kit you can pick up at Home Depot. You’ll need to buy a respirator, a disposable suit, and nitrile gloves separately.

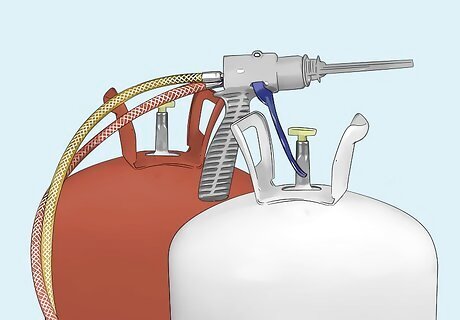

Take a thermal image of the walls to spot studs and wires. Buy or rent a thermal camera and use it to scan your walls. The cold spots (or hot spots, if it’s summer) represent the gaps in your wall. You must not drill into any wires, studs, or receptacles, and you’ll get the best insulation by drilling into the center of each wall section. Refer to the thermal imaging regularly when you’re drilling the holes into the wall. The studs, which should sit every 16–24 inches (41–61 cm) in the wall, create closed off pockets in the wall. By applying expandable insulation foam to the center of each section, the foam will spread out evenly through the wall. You can use a stud finder if you don’t want to rent or buy a thermal camera, but it’s a lot more time consuming. It’s also riskier, since a stud finder may not catch electrical lines or pipes.

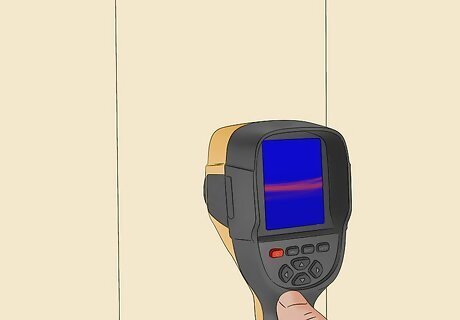

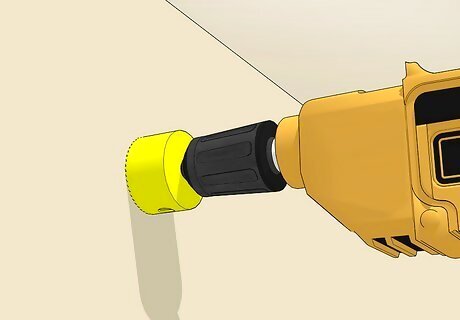

Drill holes into each section of the wall using a hole saw. Grab a hole saw that matches the size of the nozzle on your spray kit and attach it to your drill. Use your camera and a measuring tape to locate the center of each internal pocket in the walls. Then, drive a hole into the center of each section that you want to insulate. The final result should look like a series of evenly-spaced holes, all at the same height on the walls.Insulate a Wall Without Removing the Drywall Step 3Bullet1.jpg This process can also be completed from the exterior by removing the siding or drilling through the exterior. However, this is especially difficult for a non-contractor to do since you can’t rely on the thermal imaging.

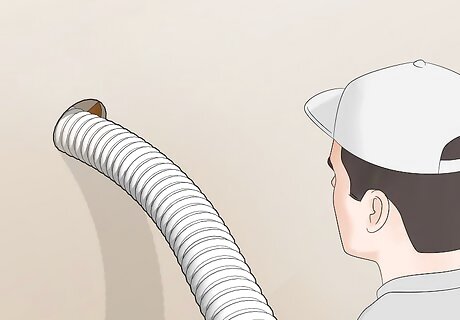

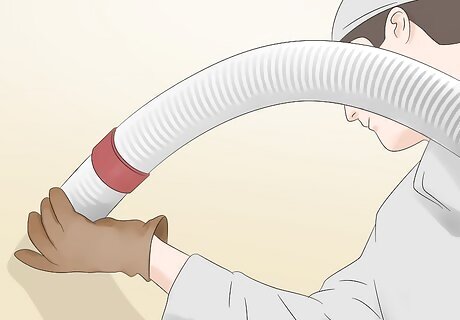

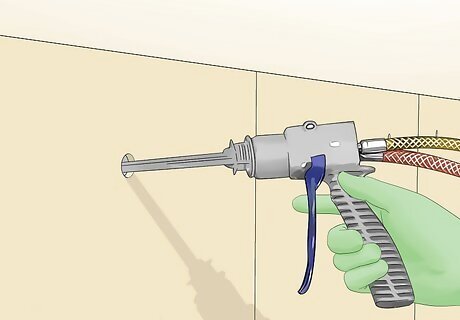

Put on your safety gear and blow the insulation into the holes. Put on your disposable suit, respirator, and gloves. Follow the manufacturer’s directions to hook up the insulation tanks. Insert the nozzle into the wall. Pull the trigger to begin filling the wall. Angle the nozzle downwards then point it upwards as soon as you see the foam reaching your height. You are not going to perfectly fill each cavity perfectly. Don’t keep spraying once the foam starts pushing back on your nozzle. Use your thermal camera to see if you’re adequately filling up the cavities. If you feel pressure coming back on the nozzle or the drywall starts bulging or buckling, stop. If you fill the wall with too much foam and it has nowhere to go, it can damage the joists, studs, or drywall.

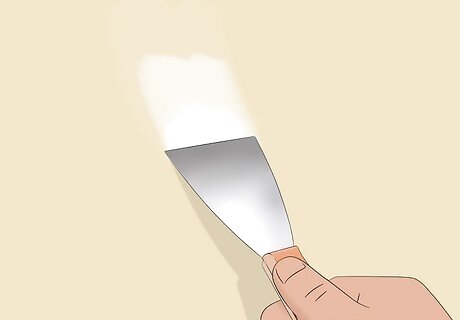

Plug the holes and paint over them to repair the walls. Once you’ve filled each section of your wall, scrape or wipe away any spray foam that sticks out from the holes. Then, wait for the foam to cure and harden (this can take up to 60 minutes). Once it has cured, patch the drywall with spackle. Wait 24 hours and sand the dried spackle before painting it to match the rest of your home. You may need to apply multiple layers of paint to ensure that the repairs blend in.

Professional Insulation Options

Blow-In Blanket Insulation (BIBS) Instead of installing injection foam yourself, you could hire a contractor to install blow-in blanket insulation. They’ll drill into your wall cavities and spray ground-up fiberglass and wool into the wall. Pros: The R-value (resistance value), which is basically how efficient the insulation is, is much higher with BIBS. This is also a much more environmentally-friendly option since the insulation is made of natural materials. Cons: BIBS installation tends to be the priciest option, since it requires specialized blowers that are designed exclusively for this process and you tend to need a lot of the blanket material.

Loose-Fill Blown-In Cellulose As another option, you could hire a contractor to blow cellulose into your walls. They’ll drill holes into your wall and then fill the walls with cellulose, which resembles thick cotton. The cellulose is then coated in boric acid, which makes the material expand slightly. It will also make the insulation fire resistant. Pros: Blown-in cellulose is much more affordable than other options. It also tends to hold up much better to pests and mold due to the boric acid. Cons: Cellulose isn’t necessarily the most efficient insulating material, and it tends to settle over time. This can cause the insulation to build up in the bottoms of your walls, which can make the insulation even less efficient over time.

Insulation Advice for Attics & Basements

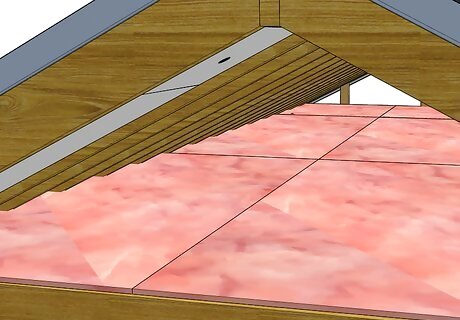

Attics With an exposed and unfinished attic, the easiest way to insulate your home is to purchase bags of loose insulation fill (fiberglass beads, cellulose, or rock wool will all work). Then, spread it around the floor of the attic to create a 7–12 inches (18–30 cm) layer of insulation. If you plan on finishing the attic in the future, lay sheets of batt insulation in between the joists on the walls so you can put drywall on top. Batt roll insulation is what most people think of when they picture insulation. It’s that pink stuff that comes in sheets. Insulating your attic is one of the most efficient ways to cut down on your energy costs.

Basements Hire a professional to insulate the basement. The type of ventilation and insulation needs depend on a variety of unique factors, and fireproofing requirements for basements can be difficult to fulfill if you don’t know what your options are. Any kind of insulation can be used in basements, but choosing the correction option can be difficult. The options here also change depending on whether your basement is finished or not. The basement is more connected to your home than the outside, so insulating it is a great way to keep your lower levels comfortable during extreme weather.

Is injectable spray foam the best option?

If you don’t mind spending more money, removing the drywall is better. Drill-and-fill retrofitting is efficient, but it’s not perfect. Regardless of how careful you are and what installation material you choose, there will be gaps somewhere. If you want the job done perfectly, removing the drywall and using closed-cell polyurethane spray foam is your best option. If you’re only insulating 1-2 rooms or walls, it may be worth it to spend a little bit more money to remove the walls. If you’ve got an older home and the insulation badly needs updating, it’s probably going to be more efficient to go the drill-and-fill route.

Comments

0 comment