views

- Fill a jar with white vinegar, add a dash of salt water, and hang two nickel anodes in it. Charge the anodes with a 6- or 12-volt battery and submerge the item to plate it.

- Your white vinegar will turn green when the fluid is charged with enough nickel to plate.

- Nickel plating will protect your item from general wear and tear. It will also increase its overall sheen and remove any tarnish.

DIY Nickel Electroplating

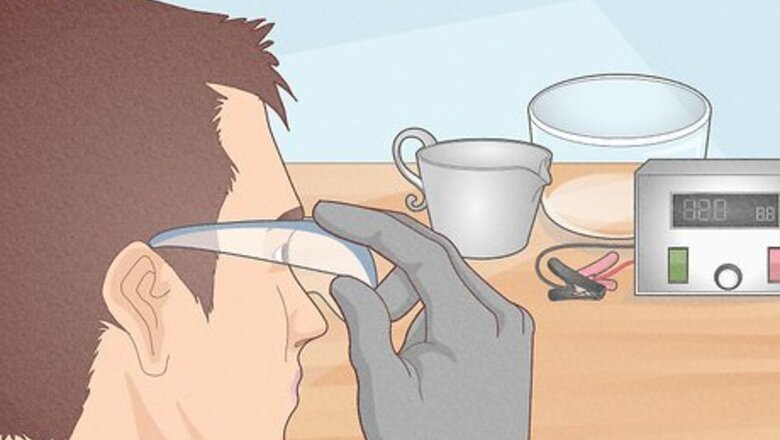

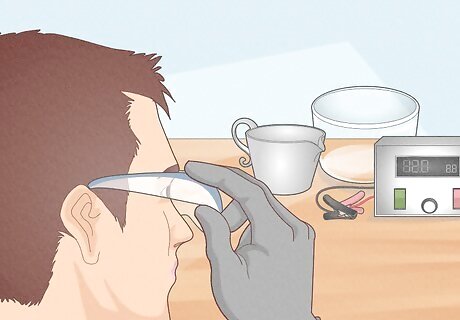

Gather your supplies and put on gloves and protective eyewear. Grab two pieces of nickel anode, some white vinegar and alligator clips for a battery or power source. Make sure that you keep the room ventilated by opening the windows and turning the fan on. This process is known as electroplating, and it’s the only DIY method you can use to nickel-plate an object. There are other methods out there, but they require industrial labs and chemicals you don’t have access to.

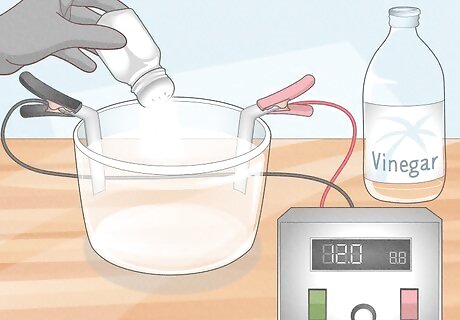

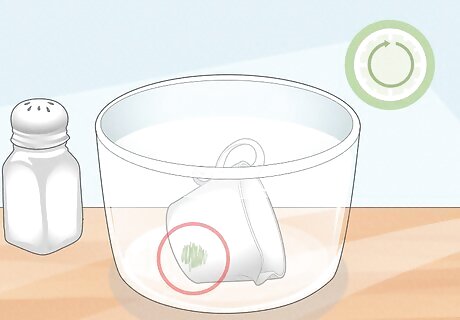

Fill a glass container with vinegar and set up your plating probes. A mason jar works best, but any glass will work. Fill the jar with white vinegar and add roughly 1 tablespoon (17 g) of salt. Hang your two pieces of nickel on the rim of the container so that they’re halfway submerged in the vinegar. Grab a small power supply and use the alligator clips to hook the positive and negative leads up to the pieces of nickel. Hook the positive wire up to one of the nickel pieces, and the negative wire to the other one. Plug the power supply in and wait. For your power supply, you can use a 6- or 12-volt battery. You can also buy a dedicated power supply with built-in alligator clips. So long as the power supply isn’t putting out more than 1 amp, this will work. You can measure the amperage by sticking multimeter probes into the vinegar solution.

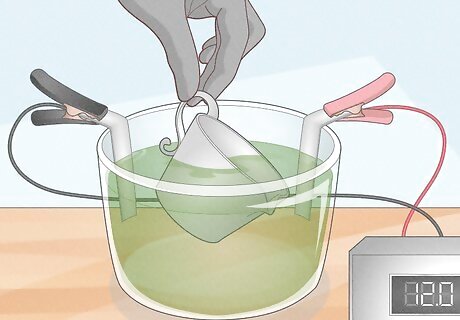

Submerge the item once the vinegar turns green. The salt, vinegar, and charged nickel anodes will flood the solution with electrolytes and cause it to turn green. Once this happens, it is charged. Clean the metal object you want to plate and disconnect the power supply. Leave the positive nickel piece hooked up where it is, but take the negative anode out. Hang your object from some copper wire and submerge it in your solution. The easiest way to hang the object is to wrap copper wire gently around the item, wrap the other portion of the copper around a pencil, and hang the pencil over the solution. The copper won’t interfere with the plating process, although it will also end up plated in nickel. Hanging your object in the solution will keep it from floating to the bottom of the container. If this happens, the plating won’t coat each side of your object evenly.

Wait roughly 20 minutes until the plating fully develops. It may take a little longer if the item is especially large, or if it has lots of grooves and textures. Periodically pull the item out to see if it is completely plated. Once you’re happy with the appearance and quality of the item, remove it and rinse it off with water to remove any charged vinegar. Keep the solution! It won’t go bad and you can use it in the future to nickel plate items so long as you keep the bottle sealed. You can complete this process on basically any metal or alloy. Popular options include items made out of gold, silver, tin, platinum, nickel, chromium, cadmium, palladium, brass, and zinc. You can even electroplate 3D prints!

Does nickel plating wear off?

Yes, nickel plating will wear away over time. However, it usually takes a long time and a heavy amount of wear and tear. There are two main benefits when it comes to nickel plating. One is that it generally looks pretty cool. The other is that it protects the underlying material from damage. So, while the nickel plating will eventually fade, it will take a long time and it’s a sign that the plating is doing its job by protecting the surface underneath. How quickly the plating wears off depends on the wear and tear of the item. Unless you’re handling it every day though, the plating could last decades. Nickel plating is heat-resistant, but it will start to wear away at temperatures higher than 750 °F (399 °C).

Removing Nickel Plating

Buy a nickel stripping agent and soak your object. Rinse your object off. Follow the instructions on your nickel plating stripping agent to heat it up. Typically, you heat the liquid up to around 140 °F (60 °C) to activate it. Then, soak your nickel-plated object in the solution for 10-15 minutes. Remove it with some tongs or a wooden spoon, rinse the object off thoroughly, and you’re done! There are other ways to do this, but it usually involves charging sulfuric acid with anodes, and it’s a little more complicated and dangerous than just using a stripping agent.

Identifying Nickel Plating

Nickel-plated items will corrode in salt water and change color. Scratch the object in question with a nail or tack to expose the metal underneath. Submerge the item in salt water for 24 hours. Nickel-plated objects will corrode in salt water, and their color will change dramatically. Authentic 100% nickel won’t corrode or change color. If you don’t want to risk damaging the item, you could always take the object to a jeweler and ask them to take a look at it. They should be able to determine if you have pure nickel or not.

Is nickel toxic to touch?

No, but avoid touching it if you’re allergic to nickel. If you are allergic to nickel and you touch something plated, you may develop contact dermatitis. Your skin may develop a rash, feel itchy, or turn red and dry. These symptoms usually go away on their own, but you should see a doctor if the symptoms get worse over time. Nickel is actually found, in trace amounts, in the air, water, and various household products.

Is nickel plating better than chrome?

Go for nickel plating if you want protection and chrome for the look. If your object is going to be exposed to a lot of other chemicals or moisture, then you’re better off doing nickel plating. Chrome is a slightly harder material, but nickel is close enough in that race that you won’t see a big difference there. The main reason to select chrome plating is that it looks neat. It’s shinier, more reflective, and has this neat blue tint when you shine a light on it. It is generally more expensive to get chrome plating, although it depends on the type of nickel plating you go for.

What color is nickel plating?

If you do this at home, it will be silver, just like regular nickel. If the process wasn’t carried out 100% correctly, your nickel may have a slightly yellow tinge. The type of plating influences the texture, but not the color. Your DIY nickel plating will come out bright and shiny. Other professional methods may leave the plating with a duller or matte finish. Professional nickel-plating services can add dyes to the nickel coating. These coatings can be any color.

Comments

0 comment