views

Threading the Machine

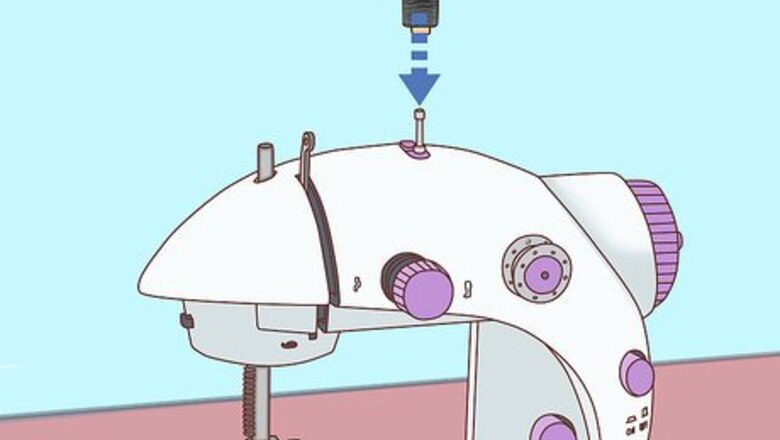

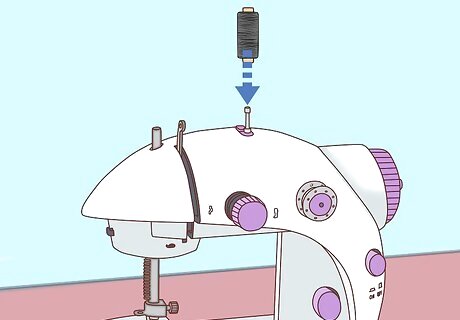

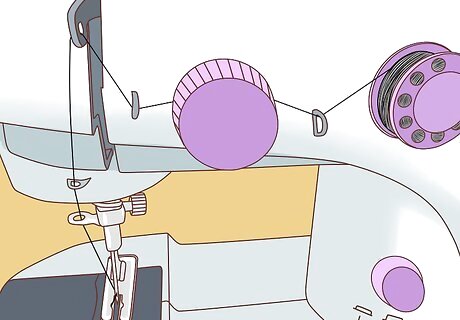

Place a spool of thread on the thread spindle. Some mini sewing machines have retractable thread spindles (vertical metal or plastic posts on the top-right of the machine). Fully extend the thread spindle by pulling it directly upwards. Then, slide a spool of thread onto the spindle. Some mini sewing machines feature a secondary bobbin spindle on the front of the machine, towards the right side. You can place a bobbin here instead of using a full-sized spool for the top thread. To use this secondary bobbin spindle, remove the cap and slide the bobbin onto the post. Then push the cap back on so the bobbin clicks into place securely. Keep the machine turned off while you thread it to avoid any accidents.

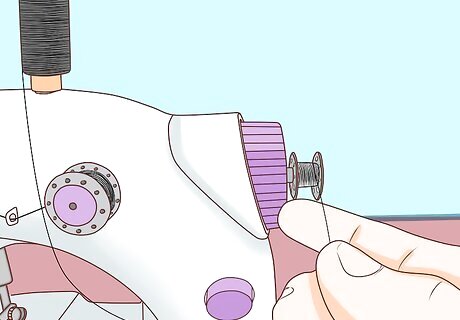

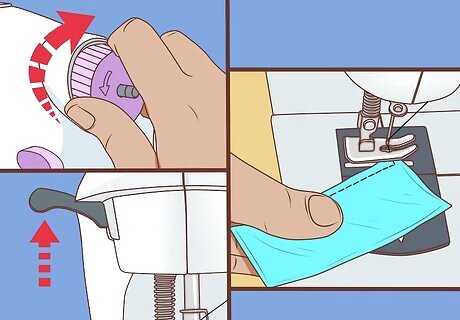

Wind an empty bobbin to fill it up with thread. Find an empty bobbin that’s compatible with your machine. With the spool of thread positioned on the thread spindle, wrap the loose end of the thread around the central post of the bobbin about 4 or 5 times in a counterclockwise direction. Press the bobbin onto the winding post, which is in the center of the hand wheel on many mini sewing machines. Hold the thread out with your hands, turn on the machine, and press down on the foot pedal. Guide the thread from side to side so it fills up around the entire post of the bobbin. When the bobbin is completely full, cut the thread to separate the bobbin from the spool.

Guide the loose end of the thread through threading mechanisms. The threading procedure for each sewing machine is slightly different, but you can pinch the end of the thread to guide it along, as directed by your machine’s instructions. Usually, you’ll pass the thread through a series of holes or hooks called thread guides along the way. With most machines, you’ll push the thread through one loop and then pull it firmly between two tension disks. After this, you’ll direct the thread through a hole or hook on the take-up lever, which moves up and down and is located on the left half of the machine, above the needle. Finally you’ll draw the thread down towards the needle, often passing through a hole below the take-up lever and another right above the needle.

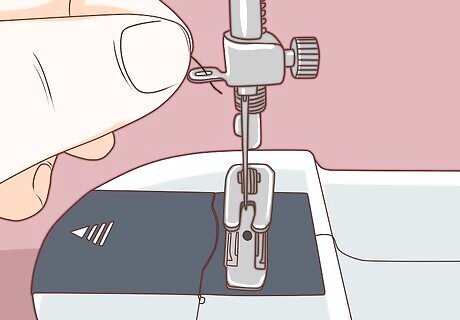

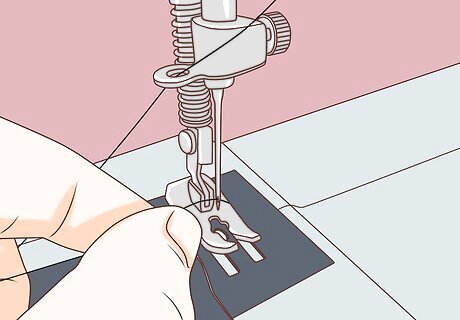

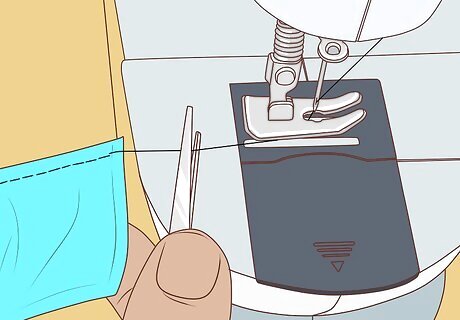

Pass the thread through the eye of the needle. Once the machine is threaded correctly, you’ll direct the end of the thread through the hole (called the eye) in the tip of the machine’s needle. Use the hand wheel to bring the needle to its highest point. Then push the thread through the eye from front to back or left to right, depending on the position of the needle. Refer to the machine’s instructions if you’re not sure which direction to thread the needle. Trim the end of the thread so that it’s smooth and not frayed, and wet it with your tongue to keep the fibers together. Once the needle is threaded, tug about 5 in (13 cm) of thread towards the back. This will prevent it from slipping back through the eye as you begin moving the machine’s mechanisms.

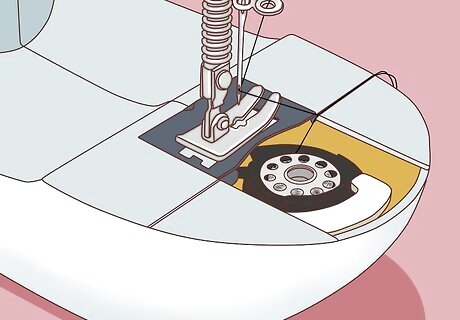

Drop the bobbin into the bobbin compartment. Slide off the cover to the bobbin compartment first. Pick up the bobbin and press it into the bobbin-shaped chamber. The bobbin should be sitting horizontally in the compartment, with the thread winding around it in a counterclockwise direction. You’ll usually need to slip the bobbin thread behind a narrow strip of metal or plastic to keep it in alignment, but check the machine’s threading instructions for guidance. The cover is a thin plastic piece that rests on top of the bobbin compartment. Slide it off, either towards the left (if the bobbin compartment is to the left of the needle) or towards you (if the compartment is directly in front of the needle). The bobbin thread should match the color and fiber content of the top spool of thread you’re using.

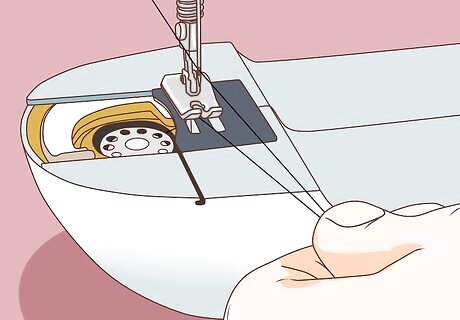

Turn the hand wheel to lower the needle so it catches the bobbin thread. Hold the loose ends of the bobbin thread and the spool of thread together in your left hand. Use your right hand to turn the hand wheel (on the right side of the machine) towards you. This will move the needle down and the top thread will catch the bobbin thread. Pull the loose ends of thread until there’s about 5 in (13 cm) of each strand extending past the needle before you turn the hand wheel. If your machine has a thread channel next to the bobbin compartment, you can slip both threads into this channel to line them up while you turn the hand wheel. Make sure you’re still holding the loose ends firmly.

Pull the loop of bobbin thread out above the feed dogs. Keep turning the hand wheel to bring the needle back up. It will pull a loop of bobbin thread up through the gap between the feed dogs (metal bars featuring a toothy texture). Tug on this loop out so that the loose end of the bobbin thread comes out of the bobbin compartment. You can gently pull the top thread upwards to expose the loop so it’s easier to grab onto. Pull the loose ends of both threads towards the back of the machine, passing them under the presser foot. Now you have a correctly-threaded machine! Slide the bobbin compartment cover back into place when you’re done.

Sewing a Machine Stitch

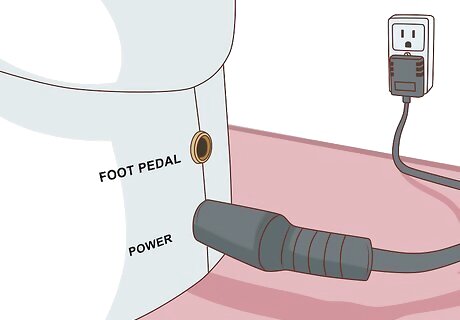

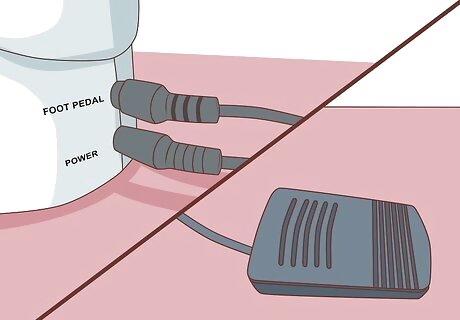

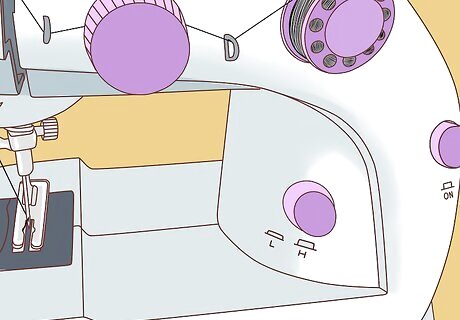

Add batteries to the machine or plug it into an external power source. If your mini sewing machines takes batteries, look at the manual to determine which type and quantity to use. If your machine uses a power cord, plug the pronged end of the power cord into the power source. Plug the other end into the correct slot (it’s usually labeled) on the lower-right side of the machine. Keep the machine turned off as you connect it to its power source to prevent any accidents.

Plug in the foot pedal and place it on the floor. The foot pedal jack connects to another slot on the right side of the machine. It’s usually labeled and will be located near the slot for the power cord. With your machine situated on your work table, and your chair set up in at the table, position the foot pedal on the floor. Your right foot should be able to comfortably reach and press the pedal. The narrow end of the pedal should be closest to you. Think of the foot pedal like the gas pedal of a car. When you press it, the machine will run.

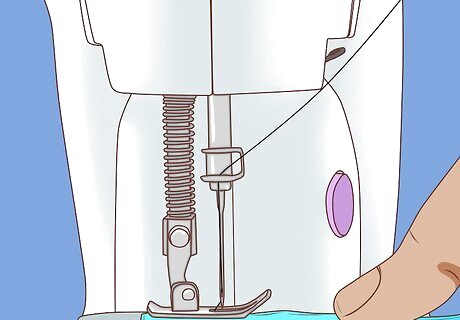

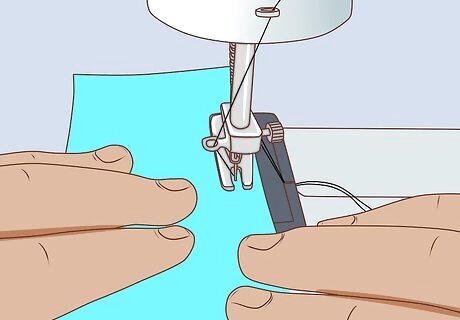

Position your fabric under the raised presser foot and needle. Turn the hand wheel towards you to raise the needle to its highest position. Then, push the presser foot lever upwards with your left hand to raise the presser foot. The lever can usually be found on the back of the machine. With both mechanisms lifted, slip the edge of the fabric underneath the presser foot. Center the fabric you want to stitch directly under the needle. It’s helpful to start with a test scrap of fabric before moving onto your project. Align the fabric so that only about ⁄2 in (1.3 cm) of fabric extends past the needle. The end of the fabric should align with the back side of the presser foot. If you don’t have enough fabric past the needle to begin with, it might get sucked down between the presser feet. This will jam up the machine. You should never sew directly over pins. Remove any pins as you go, before sewing the seam.

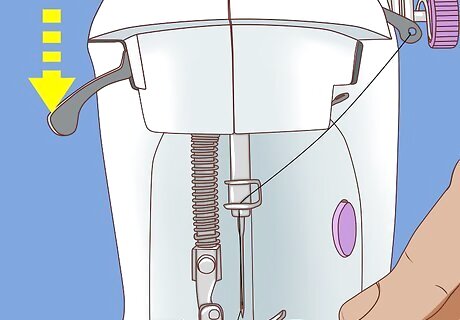

Lower the presser foot and needle. Push the presser foot lever downwards so that it comes into contact with the fabric. Then turn the hand wheel to lower the needle into the fabric. Before you begin stitching, hold onto the loose ends of both threads, gently pulling them them taut towards the back of the machine. This will ensure your stitching gets off to a good start and that the machine doesn’t come unthreaded.

Apply steady pressure to the foot pedal to begin sewing. Once the machine is correctly threaded and the fabric is in place, you can turn the machine on using the power switch. Press the foot pedal with your right foot, as you would press the gas pedal on a car, to engage the machine and begin stitching. The fabric will move away from you, towards the back of the machine. Use your hands to gently guide the fabric, but keep them well away from the needle for safety. You can press the backstitch button or lever (usually located on the front of the machine) to make a few stitches in the opposite direction. Do this at the start and end of your row of stitches to prevent them from unraveling.

Lift up the presser foot and needle before pulling out the fabric. When you’re done stitching, turn the hand wheel towards you to raise the needle out of the fabric. Pull up the presser foot lever to lift the presser foot as well. With the fabric freed up, you can pull it out from under the machine’s mechanisms. Move the fabric gently, since the threads are still connected. You also don’t want to tug on the fabric too hard as this could break the needle.

Cut the threads loose. Some machines have a small blade called a thread cutter on the left side or the back of the machine. Pull both threads taut over the blade and tug firmly to cut it. Alternatively, you can use a pair of snips or scissors to trim the thread. Trim the thread as closely to the fabric as you can for the neatest finish. This will also help prevent the thread from coming out of the needle, so you'll be ready for your next stitching project.

Adjusting the Machine Settings

Turn the tension dial to get even stitch tension. If you notice your top row of stitches is loose and loopy, twist the tension dial clockwise to tighten the tension on the top thread. If you have the opposite problem, with tight top stitches and loose bottom stitches, turn the tension dial counterclockwise to loosen the tension on the top thread. The tension dial controls the tension disks that you sandwiched the top thread between when you threaded the machine. Sometimes it will feature numbers to indicate which tension setting you’re using. If you’re switching between thin fabric and thick fabric or bulky layers of material, you’ll likely need to adjust the tension. It’s always useful to do a test row of stitches on a scrap piece of your fabric to see if you need to adjust the tension.

Select a high or low speed setting. Although you can control the up-and-down movement of the needle by pressing the foot pedal, you can choose whether you want the needle to move quickly or slowly with the speed setting. Many mini sewing machines come with a button for controlling this. If you push the button inwards, it’ll select the low speed setting, and if you leave it outwards, it’ll operate on the high speed setting. Other machines have a side-to-side switch or a numbered speed setting. Check the machine’s manual to for instructions on how to control your machine’s speed.

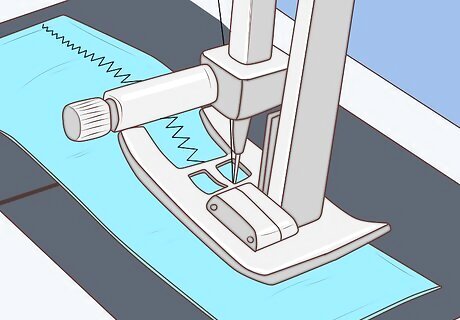

Choose a stitch type and length. Some mini sewing machines come with additional features that let you choose between straight, zig-zag, and decorative stitches as well as short, medium, and long stitch lengths. Typically these can be controlled by twisting a dial which is printed with each stitch type, as well as another dial or switch that selects the stitch length. Refer to your machine’s manual for the full range of settings. Select the stitch type and length before you begin sewing, not while you’re sewing.

Comments

0 comment