views

- Strike the screw with a hammer to loosen it. Then, soak it in rust penetrant and remove it with a screwdriver.

- If a hammer doesn't work, use a gas torch to heat the screw until it smokes. Cool it with water, then remove the screw with a screwdriver.

- If you're working with a stripped screw, cut new grooves into it with a rotary tool.

Hammer and Screwdriver

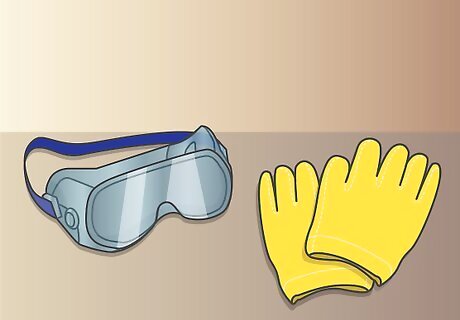

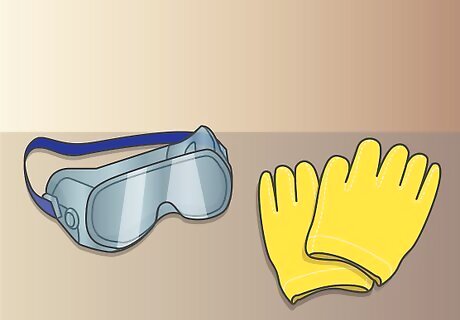

Wear thick leather gloves and safety glasses to protect yourself. Keep the gloves on throughout the process in case you slip and hit your hands. It will mitigate at least some of the damage. Also, rusted metal can break and splinter, so wearing polycarbonate glasses or goggles is a must.

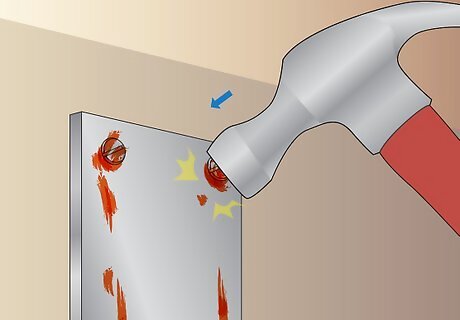

Strike the screw a few times with a metal hammer. Square up the hammer so it is directly over the screw's head. Rapidly hit the head a few times to break the rust seal holding the screw in place. Use some force if you can, enough to jar the screw while still maintaining your accuracy. Keep your other hand clear from the area in case the hammer misses the screw head.

Soak the screw in rust penetrant for 15 minutes. Commercial rust penetrant often comes in a spray bottle, so all you need to do is point the nozzle and shoot. Spray a lot of penetrant around the screw's head. This should lubricate the head as well as allow penetrant to drip down into the screw's shaft. You can purchase rust penetrant at most hardware and general stores. If you don't have rust penetrant on hand, you can mix your own by combining equal amounts of acetone and transmission fluid. Regular WD-40 can help, but it isn't as effective as specialty rust penetrants.

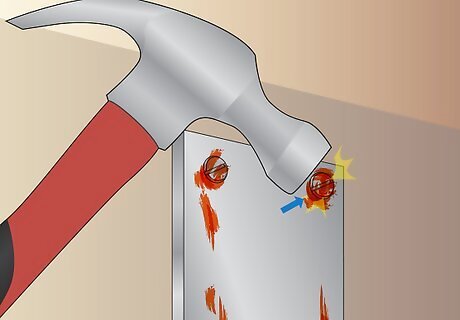

Hit the screw a few times and tap around the head. Give the screw a few more solid whacks with your hammer to loosen the rust further. Afterwards, lightly hit the side of the screw head. Do this all the way around the head to prepare the screw for removal. Hitting the screw with an impact driver and hammer may also help break up any remaining rust.

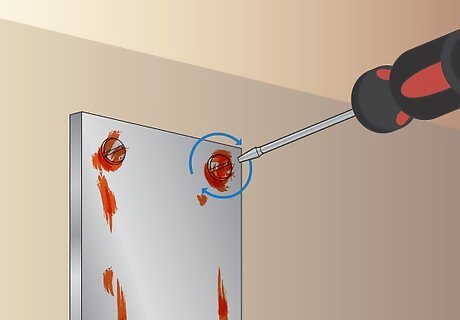

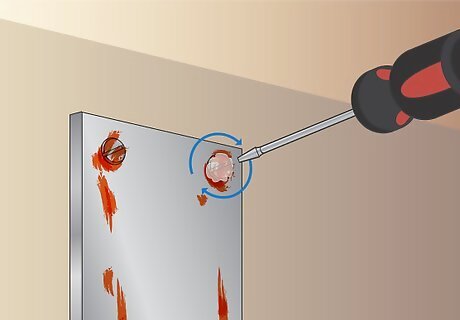

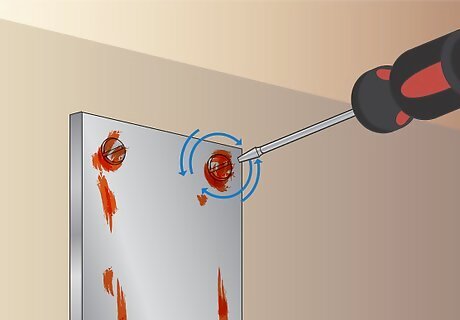

Remove the screw with a screwdriver. Use the correct type of screwdriver for the job, such as a Phillips head screwdriver for those screws with +-shaped slots. Turn the screw counterclockwise to remove it, but stop if you experience problems like the screwdriver beginning to strip the screw. You can end up making the removal more difficult if you keep going. Stop turning the screw if you feel like you can't keep the screwdriver in the screw head. The screwdriver may even slip out. This happens when the screwdriver begins stripping the screw.

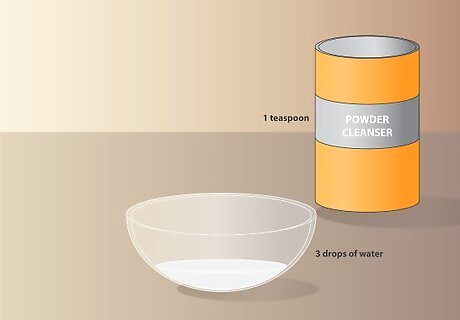

Create a gripping paste with water and cleanser for stuck screws. The gripping paste will help you keep your screwdriver in place without damaging the screw. First, place 1 teaspoon, or .17 oz (4.8 g), of a powdered cleanser in a mixing bowl. Add about 3 drops of room temperature water, then stir the mixture into a paste. Spread the paste over the screw head with a rag. You can use a regular kitchen or bathroom cleanser. You may already have some on hand. If you don't want to mix your own paste, you can apply automotive valve grinding compound to the screw head instead.

Attempt to remove the screw again with a screwdriver. Push the screwdriver through the paste and into the screw head. Twist the screw counterclockwise again while continuing to push down. The force may finally break through the rust, freeing the screw. If this doesn't work, you can generate more force by turning the screw with a box-end wrench. Hold the screw in place with the screwdriver.

Heat

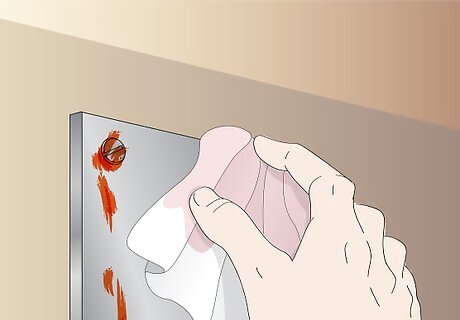

Wipe the screw off with a water-based degreaser. Cleaning the screw is especially important after attempting to remove it through other methods. Heat can cause rust penetrant and other chemicals to catch fire. To prevent this, dampen a rag with the degreaser, then wipe down as much of the screw as possible. You can buy degreaser at a home improvement store, or you can make your own with vinegar or baking soda. Be sure to dispose of oily rags properly. Leave them to dry on a non-flammable surface out of direct sunlight. Throw them in the trash after they harden.

Wear leather gloves and keep a fire extinguisher nearby. Take full safety precautions to minimize the risk of accidents from using heat. A good pair of thick gloves can protect your hands from burns, while the extinguisher can prevent sudden fires from turning into a serious emergency. Wait to put the gloves on until after you clean the screw. This way, you won't get any potentially hazardous degreaser on a good pair of gloves. Even if you are sure you wiped away all of the flammable chemicals, keep a fire extinguisher nearby just in case.

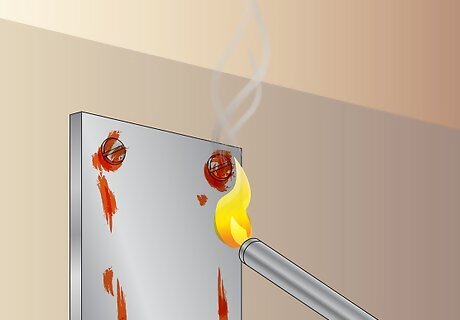

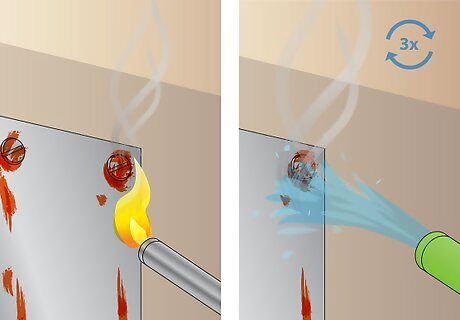

Heat the screw with a gas torch until it smokes. Although a cigarette lighter may do the trick, you get better control by using a torch. Any butane or propane gas torch is safe to use for this project. Light the torch, then lower the tip of the flame to the screw's head. Wait for the screw to emit steam and smoke. To avoid overheating the screw, keep the torch back so only the tip of the flame touches the screw. If the screw starts turning a cherry red color, move the flame away. You never want it to get this hot.

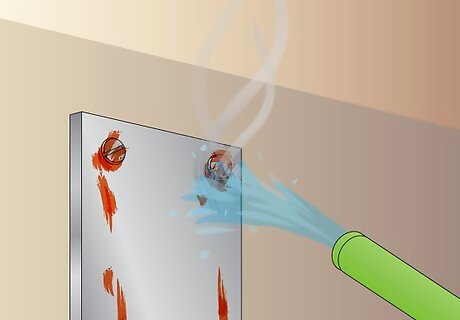

Soak the screw immediately with cold water. If you have a garden hose on hand, you can spray the screw until it is cold again. Otherwise, soak it by pouring water from a bucket or by wiping it with a wet rag. Wait until you can no longer feel heat radiating from the screw. Heating the screw causes it to expand, while cooling it causes it to contract. Doing this rapidly increases the chances of the rust seal breaking.

Repeat heating and cooling the screw 2 or 3 times. While you can try removing the screw right away, you usually need a few heat cycles to free stubborn screws. Use the torch to heat the screw head, then immediately douse it in cold water. If you find that you cannot remove the screw later, you can always try heating and cooling it again.

Use a screwdriver to remove the screw. Choose a screwdriver that matches the screw's head. If you do this after cutting a slot into the screw, you will need to use a flat blade screwdriver. Twist the screw counterclockwise to loosen it. Make sure the screw is completely cool to the touch. You can test it by holding your hand over it. If you feel heat coming from it, add cold water.

Apply rust penetrant if the screw is still stuck. Pour a generous amount of penetrant over the screw head. As it drips down the screw's sides, turn the screw back and forth to help spread the penetrant. Finally you should be able to free the screw with the screwdriver. You may need to apply penetrant a few times before the screw comes free. Keep twisting the screw back and forth so the penetrant soaks in.

Cutting Grooves

Wear heavy leather gloves and protective goggles. Keep the gloves on at all times to protect your hands. They will protect you in case any of the tools slip when in use. Also, put on polycarbonate protective glasses or goggles to shield your eyes from metal fragments.

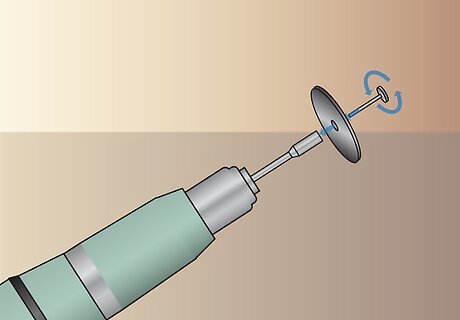

Place a cutting wheel on a rotary tool. Rotary tools have detachable heads. You can swap out the heads with 1 of many different accessories. For cutting screws, you want a flat wheel designed to cut through metal. Fit it onto the rotary tool according to the manufacturer's instructions. Test the wheel by turning on the rotary tool. The wheel should spin freely at a consistent speed.

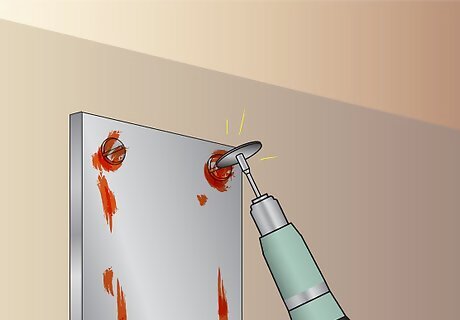

Cut a slot the size of your largest screwdriver into the screw head. Keep your biggest flat blade screwdriver nearby to use as a point of comparison. Tip the rotary tool so the edge of the wheel is over the screw head. Lower the tool down to begin cutting into the screw. Work slowly and carefully to widen the cut to the size you need. An ideal slot creates a tight fit for the screwdriver so you can turn the screw with maximum force.

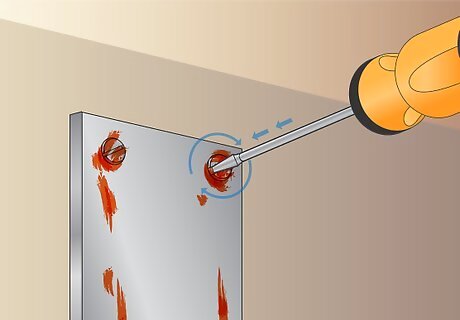

Use the screwdriver to remove the screw. Push the screwdriver head into the slot you made. Continue pushing down on the screw as you begin turning it counterclockwise. If the slot is effective, the screw will loosen and pop out. If the slot is too small, you can widen it with the rotary tool. If the slot is too big, you may not be able to remove the screw this way unless you can find a larger screwdriver. Some screws will still be rusted in place even after you cut a perfect slot. Use heat to remove them.

Comments

0 comment