views

- Use polyurethane varnish for dependable waterproofing, wood stain for weather-proofing, oil for a cheap, light sealant, or epoxy for a more thorough, durable finish.

- Sand your plywood before applying any sealant. Make sure your sealant of choice coats the plywood completely for total waterproofing.

- Allow ample time for the sealant to dry and cure so that it can work as intended.

Preparing the Plywood

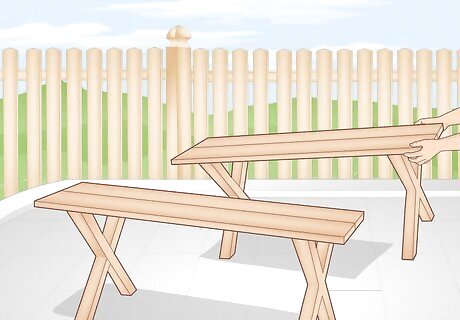

Set up a clean workspace. Find a flat, outdoor area, and make sure it’s clear of any objects that you wouldn’t want to accidentally get paint on. Then, set up a place to rest your plywood while you seal it. This could be a sawhorse, some newspaper or tarp laid flat on the ground, or up against a wall you don’t mind getting a little dirty.

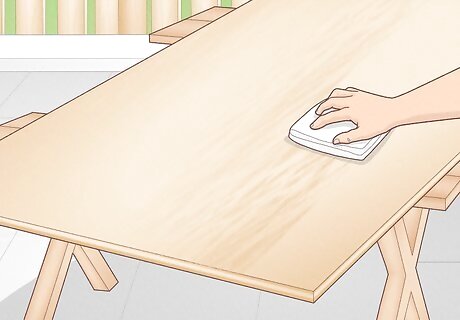

Use a damp cloth to wipe dust off the plywood. This will help prepare the surface for sanding, clearing away any debris that might interfere with the process. If your length of plywood is especially rough at the start, vacuum any debris off of it using the brush extension of a vacuum.

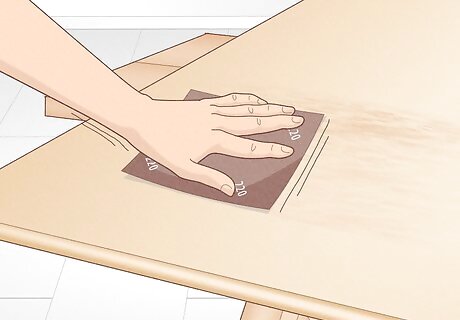

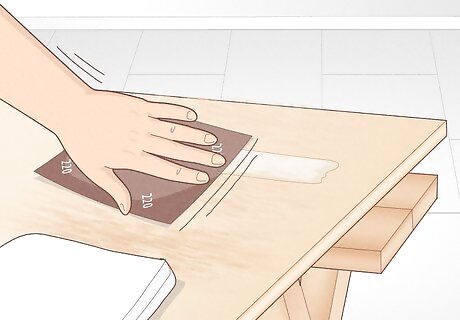

Sand the surface with 180 to 220-grit sandpaper. Rubbing along the grain of the wood, stroke the plywood back and forth with a square of 180 to 220-grit sandpaper. Be patient, and sand the entire area of each board evenly, taking care not to neglect any spots. Sand until the board is smooth and the sandpaper doesn’t seem to have any further effect. Also sand the sides and ends of the boards, but be sure to follow the grain! The ends can be particularly rough and coarse. For these, use 80-grit sandpaper.

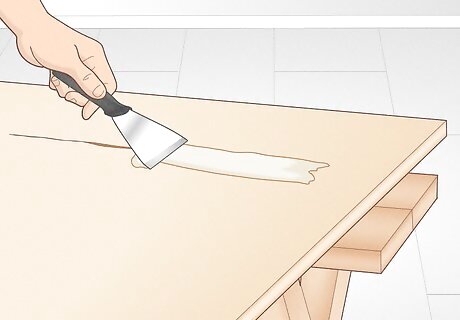

Examine the plywood and fill in any divots with wood putty or wood filler. Apply a small amount of putty or wood filler to a putty knife, and spread it across the divot using the knife’s flat edge. Be sure the gap is completely filled, then scrape away any excess putty. Also apply putty to any divots on the ends and sides of the board. Let the putty or filler dry overnight before you proceed.

Sand and wipe the surface with a damp cloth to smooth out the excess putty. Once the putty or filler has dried, sand the plywood again using 220-grit sandpaper. Pay extra attention to areas where you used wood putty, and sight down the board to make sure these areas are level with the rest of the board. Once finished, wipe down the surface with a damp cloth to remove any excess dust and debris. Then, let the plywood dry completely overnight.

Using Polyurethane Varnish to Seal Plywood

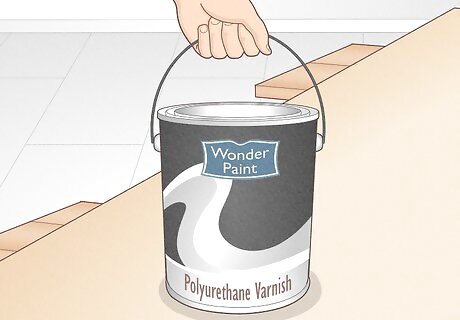

Use polyurethane varnish for dependable waterproofing. This product is a common sealant that provides good general waterproofing as well as a nice finish to the project at a reasonable cost. It’s easy to handle and doesn’t require too much skill to apply.

Apply sanding sealer to the front and back of the plywood. Before you apply polyurethane sealer, apply a coat of sanding sealer in order to prime the board. Mix the sanding sealer with a paint stick. Then, with a paintbrush, apply a thin coat of sealer onto the board and let it dry for about an hour, then apply the sealer to the back of the board, as well. After, sand both surfaces with fine-grit sandpaper, such as 220-grit, vacuum the sawdust from the board, and wipe it clean with a tack cloth or a spare rag.

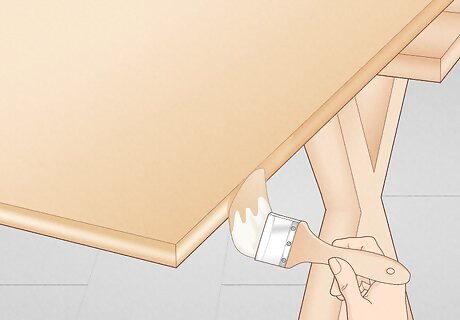

Use a clean paintbrush to apply the varnish. Use long strokes along the grain of the wood to completely cover the board with a thin coat of varnish. Allow this first coat to dry completely, then apply a second coat and let it dry again. Once these two coats have dried, flip the board over and apply two coats to the back, as before. Oil-based polyurethane varnish takes about 6 hours to dry, and water-based varnish takes about 24 hours. Be sure to note which kind you have, and allow enough time for it to dry completely between applications.

Apply varnish to the edges and ends. Using a smaller paintbrush, apply polyurethane varnish to the ends and along the sides of the board. Let it dry, then apply a second coat and let that dry, as well. Use polyurethane varnish on the sides and another sealant on the broad faces of the board if you’d like a different finish for the broad faces of the board. If you do this, use masking tape to protect the faces of the board, since other sealants won’t apply well on top of polyurethane varnish.

Allow the varnish to cure for 30 days. Polyurethane varnish takes a while to cure, so let the boards rest for about a month before you proceed with your project or install them outdoors.

Using a Water-Based Stain to Seal Plywood

Choose a standard wood stain for general weather-proofing. In addition, these stains provide a nice and aesthetically-pleasing finish. Wood stains will also give you a better seal than just typical paint.

Pour the water-based stain into a garden sprayer. These sprayers are most often used for spraying pesticides, but they work well for applying sealants and stains to wood, too. If your stain requires it, mix the stain with water or another diluter indicated on the packaging before pouring it into a sprayer.

Spray a layer of stain onto both sides of the plywood. Using the garden sprayer, evenly coat the plywood with a first coat of stain. Be sure to cover the entire board, as well as the edges, then let the stain dry for 10-15 minutes, or as long as the instructions indicate. Once dried, use a rag to clean off the excess stain, then flip the board over and repeat this step on the other side.

Let the plywood sit for 24 hours. Once the stain has dried for the allotted time, allow the stained plywood to rest for at least a day to cure. Repeat the process with another coat in order to reach your desired color and finish.

Using Oil to Waterproof Plywood

Use an oil for a relatively cheap and lighter waterproofing sealant. These are better for moisture management, and so are more suited for instances where less outright waterproofing is needed.

Purchase tung oil, boiled linseed oil, or mineral oil. Tung oil is the most water-resistant and provides the hardest finish, while boiled linseed oil and mineral oil tend to be cheaper. You can use a combination of oils, so long as you allow the first oil to soak in completely before you apply the next.

Apply oil onto the flat plywood surface. Lay the plywood completely flat so that the oil doesn’t run off the edges, then generously pour the oil onto the plywood. Let the oil sit for a few minutes and begin soaking into the wood. Once the oil has soaked in, apply more until the board is completely saturated.

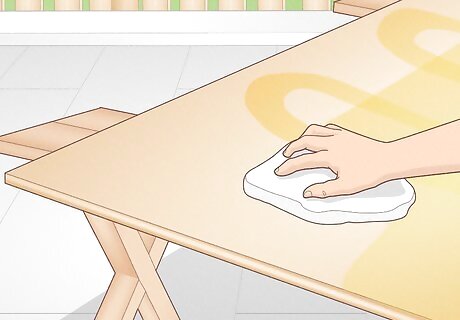

Rub the oil into the board, and wipe off the excess. With a cloth or an old T-shirt, remove any excess oil on the surface of the board, and rub this oil into less-saturated spots as you go. Use a sturdy cloth that won’t pill up or leave behind any threads or other material, like a new microfiber towel. Turn the board over to make sure the oil has saturated all the way through to the back. If it hasn’t, repeat this step on the back of the board.

Sand the board and apply a second coat of oil. Using coarse (such as 80-grit), wet-or-dry sandpaper, give the board another sanding to create a small layer of sawdust. Then, apply another round of oil as before, this time letting the oil mix with the sawdust. The oil will take the sawdust into the plywood as it absorbs, which will help to fill the pores of the wood. Let the oil soak in completely. There’s no need to wait for the board to dry with this method, since the oil works simply by saturating the board before any water can. Oil and water don’t mix, after all!

Sealing Plywood with Epoxy

Go with epoxy for a more thorough, durable finish. Epoxy might be a time-intensive, laborious, and expensive process, but the results are sturdy and suitable for things like dining surfaces and long-lasting fixtures.

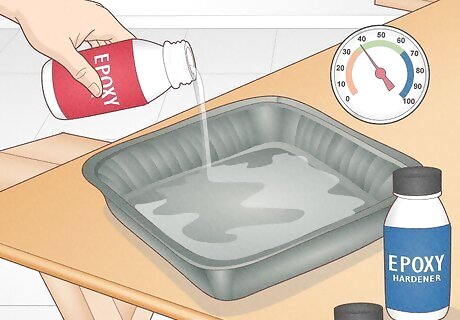

Mix the epoxy and apply it on a warm, low-humidity day. Many epoxy solutions require a little bit of prep, which typically involves combining the epoxy resin with a hardener. Follow the instructions on your epoxy product to prepare the mixture. Then be sure conditions are right for the application–avoid applying in cold temperatures or on days with high humidity, as this could interfere with how the epoxy cures. Be sure to use an epoxy that indicates it’s suitable for use on wood. Most products labeled “epoxy resin” should do, though it’s best to choose a product advertised for wood in particular, such as tabletop resins, which are designed for use in kitchens.

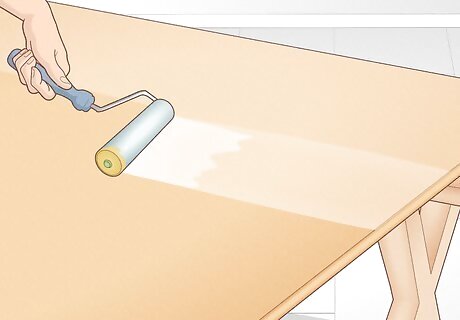

Apply the mixed epoxy with a roller. Pour a small amount of epoxy onto the flat plywood, and spread a thin layer over the entire surface using a roller or a squeegee. Then, lightly drag another, clean roller over the applied epoxy in order to flatten it and remove any air bubbles.

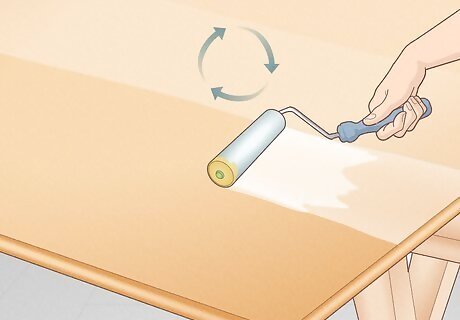

Apply a second and third coat. Wait until the first coat of epoxy is slightly tacky–about the stickiness of masking tape (this occurs about halfway through a full cure, and so could take 3-4 hours)–then apply a second coat using the same method used for the first coat. Once this second coat is tacky, apply a third coat. As the epoxy cures and becomes tacky, pass a hair dryer over the surface to remove any air bubbles.

Let the epoxy cure for at least a week before use. After you’ve applied the final coat of epoxy, let the epoxied plywood sit for one to two weeks, until the epoxy has completely hardened. Keep the board dry and at room temperature for this duration. Once the epoxy has cured for at least a week, you can repeat this process on the backside of the board if desired.

Use a UV-resistant clear coating to seal the epoxy. Once the final coat of epoxy has completely cured, protect it against UV rays using a UV-resistant top coat. These include polyurethane paints, latex paints, and epoxy paints. Use a paint roller or paint brush to apply a thin, even coat to the front, back, and sides of the board, allowing enough time as indicated on the packaging to dry in between applications. Drying time varies by product, so follow the particular product’s application instructions to allow the top coat to dry completely.

Comments

0 comment