views

Rig Site Preparation

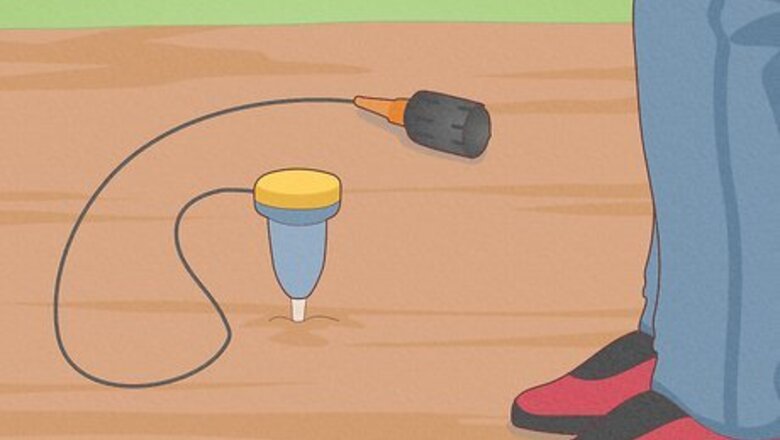

Identify the drilling site. New oil fields are most easily found where oil is already being drilled. There are a number of ways to test for oil. Soil gas surveys can assist in the discovery of oil. These surveys measure a soil sample for trace amounts of light hydrocarbons (the tell-tale chemical signals of oil). Soil gas surveys should be the first option when investigating whether a region contains oil because the test is relatively low-cost. Seismic imaging can also help locate oil deposits. Seismologists, armed with devices known as geophones, can bounce sound waves off underground rock and listen to the echoes the sound waves produce. Analyzing the echo patterns can provide accurate imagery of subsurface geology, including pockets of oil and other fossil fuels.

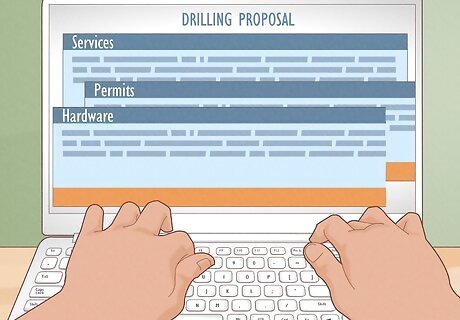

Draft a drilling proposal. After conducting the requisite research, an oil company should consider potential complications with their drilling plan and address them in their proposal. How much money is allocated for the drilling project? How long is the well expected to be productive? What is the desired return on investment? Ask hard questions and try to anticipate specific dates for key events -- such as the full assembly of the oil rig, commencement of oil production, and well abandonment -- over the course of the well's life. Conduct research into the oil market. There are lots of alternatives to oil today, including solar, electric, and biofuels. Consider recent trends in the price of oil and use it determine if drilling a new oil well is a sound investment. Is there a glut (overproduction) in the market? Are more wells expected to open elsewhere soon? If the market is volatile, with lots of wells opening and then shutting down soon after, consider waiting for a less tempestuous market before drilling.

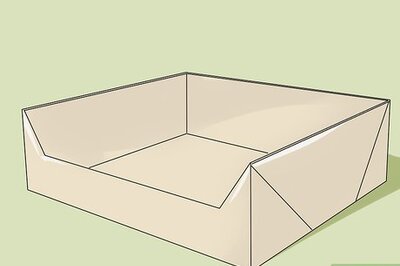

Establish infrastructure for the drilling site. It may be necessary to build a road to access the drilling site, or purchase boats if drilling an offshore well. Water, electricity, food, and sanitation equipment will also need to be accounted for. If drilling in a more developed urban area, infrastructure costs will be less significant. Preparations will vary depending on the type of environment the well is being drilled in. An offshore well, for example, will require a different set of equipment than will a conventional terrestrial (land-based) oil well. Likewise, preparations for a well drilled into frozen tundra will differ from those of a well drilled in the desert. To prepare drilling in an offshore well, a base consisting of permanent casting will need to be positioned on-site. The oil company will then affix a template (a large box resembling a cookie-cutter) to the base to to provide guidance for future drills. The drilling platform itself will then be attached to the template.

Hire staff to assist the effort. In addition to scientists and technical staff, drillers and maintenance personnel will be needed to oversee daily operations. Geologists will study surface features, terrain, and rock and soil types. Consult ecologists to ensure local wildlife will not be adversely affected. Lawyers and company officials will help ensure all the necessary paperwork is in order. Be sure to enlist the assistance of construction crews help prepare the site. Hire seasoned drillers. They should be in excellent physical shape and enjoy working with machinery. A well 10,000 feet deep requires approximately 50-75 people to operate.

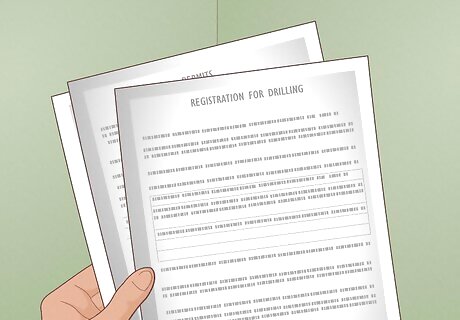

Finalize the paperwork. Obtain any permits, lease agreements, titles, etc., needed to drill in the area. Measure any impact the drilling will have on the environment and report it to the appropriate authorities. Paperwork requirements vary by state, but some of the most common types of permits needed include: Registration for well operation. This is the most basic declaration by a company describing their intent to drill, including where, how, and to what depth they will drill the well. Designation of agent or operator. This form is required when a company or individual is drilling the well on behalf of another company or individual, and identifies which employees are allowed to file paperwork and make decisions regarding the drilling process. Location assessment to determine if the well will disrupt or endanger local ecosystems or aquifers. Letter of credit, financial assurance statement, or performance bonds. These forms (and their accompanying fees) act like a deposit in a rental agreement, and ensure that the oil company will plug, sell, or otherwise decommission the well in accordance with local law and best practices. If the well is being reopened, is changing hands, or is being altered, complete the appropriate forms will need to be completed. Check with the governing land management agency to ensure all paperwork is filled out properly before drilling begins.

Take precautions. Mark the targeted area for drilling. Ensure all personnel are briefed on safety regulations and enforce them strictly. Once drilling is set to commence, place buoys around the area if drilling an offshore well. Use GPS coordinates to mark a designated spot when drilling on land. Install a blowout preventer (BOP) before beginning any actual drilling. The BOP contains high-pressure safety valves which prevent oil from escaping in the event of a blowout.

Drilling Process

Dig in! Before drilling the actual oil well, the interested company will have to do a lot of digging. Begin by clearing and leveling the designated area. Then dig an earthen pit (to prevent soil and water contamination), two larger holes (the “rat” and “mouse” holes) to hold piping and equipment, and a pilot hole (to guide the rest of the operation). These are essential to establishing an organized oil drilling operation. For expanded storage space, install a "cellar," a four-walled steel structure planted in the ground near the well site for the purpose of equipment storage. An oil company might also dig a reserve pit and line it with plastic. This pit will be used to dispose of rock cuttings and used drilling mud. In an offshore (submerged) oil well, space for storing equipment and all infrastructure needs are built directly into the oil platform.

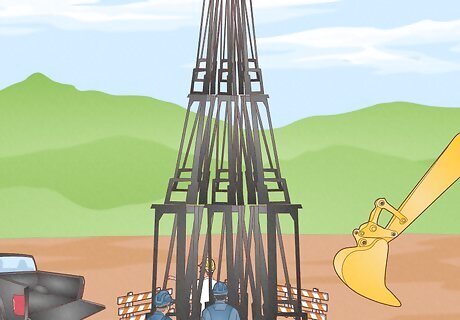

Assemble the oil rig. The rig is the complex of equipment containing the drills, pumps, and other machinery needed to drill the oil well. The deeper the well, the stronger the rig will need to be. Land rigs are usually trucked in pieces to the site and then assembled, while offshore wells will have the rig integrated into the oil platform. Offshore oil rigs will need more stability than onshore rigs.ref>http://www.entranceconsulting.com/2013/10/23/onshore-versus-offshore-drilling/

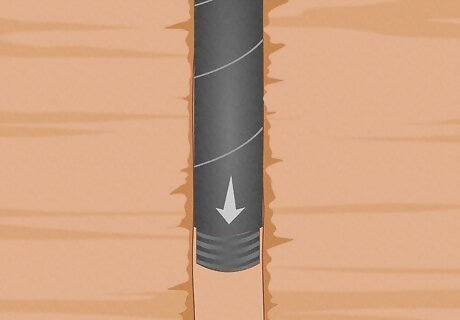

Select a drill. Most drills today are tricorne rotary drills. These drills feature a solid fixed cone at the bottom of the drill with three sets of steel or diamond-tipped teeth. Depending on the local geology, these drills can pummel through thousands of feet of rock per day.

Identify where the oil is before drilling. Depending on the location of the oil, either a vertical hole (in which the drill moves in a straight up and down path) or a horizontal hole (in which the drill is inserted at an angle to access a distant oil deposit) will be required.

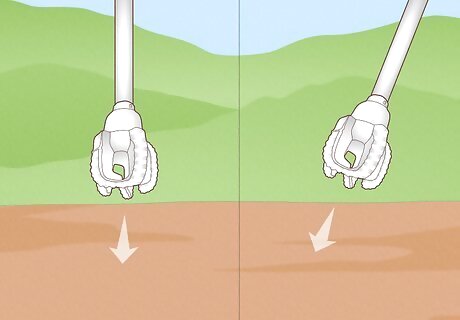

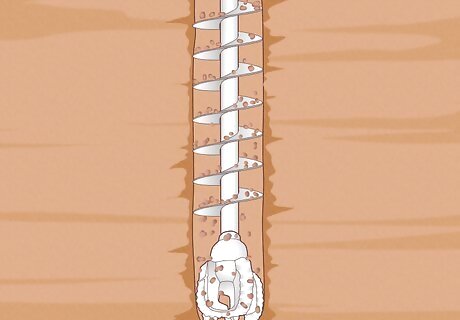

Prepare to install casing pipe. This is the first of two stages of the drilling process. To prepare for casing installation, drill a conductor hole (also known as a starter hole). The conductor hole is shallow (typically 100-200 feet deep) but has a large diameter. While drilling, pump "mud" (also known as drilling fluid, mostly bentonite or a combination of water and other chemicals) into the well to cool the drill bit, flush out bits of broken rock (cuttings), and balance hydrostatic pressure. Cuttings and mud will have to be trucked away from the site if the drilling is being performed in an ecologically sensitive area.

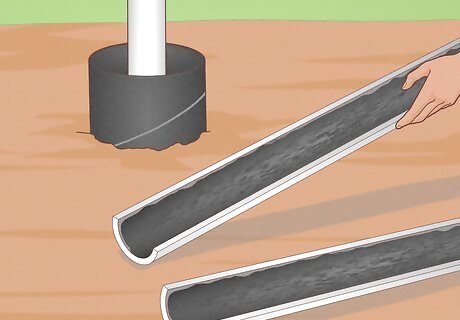

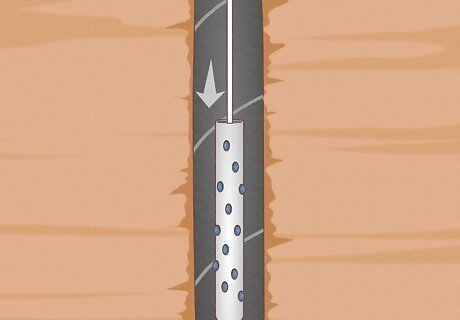

Remove the drill and insert casing pipe into the conductor hole. Casing pipe is a long metal tube inserted into the well to the depth at which the oil company believe oil can be found. Fill the space between the rock and casing pipe with cement. This will protect the water table, aquifers, and surrounding soils from contamination. Let the cement harden.

Determine if the reservoir rock (the rock layer in which the presence of oil is suspected to exist) has been reached. To do so, test rock samples, measure pressure, and lower gas sensors into the well hole. Drill deeper if the desired depth has not been reached. Stop drilling when the rock cuttings contain signs of oil sand from the reservoir rock. Some modern drills contain Measurement While Drilling (MWD) technology which relays important information about the well to the surface. MWD technology saves time since it does not require the removal of the drill each time measurements need to be taken.

Insert small diameter tubing and a perforating gun into the hole. The small diameter tubing will allow oil to flow up the length of the well. The perforating gun, when fired, will punch holes through the casing and cement, allowing trapped oil into the well.

Consider the next steps. If the well yields oil, continue on to well completion by removing the BOP and installing a pump jack or production well-head (a "Christmas tree"). If the well is not productive, seal it off with cement plugs and drilling mud. In either case, disassemble and remove the rig.

Comments

0 comment