views

Some specialized tasks may call for using silver solder to join other materials, such as brass or copper. In those cases, you may wish to look for more specific information on that process, such as soldering copper tubing.

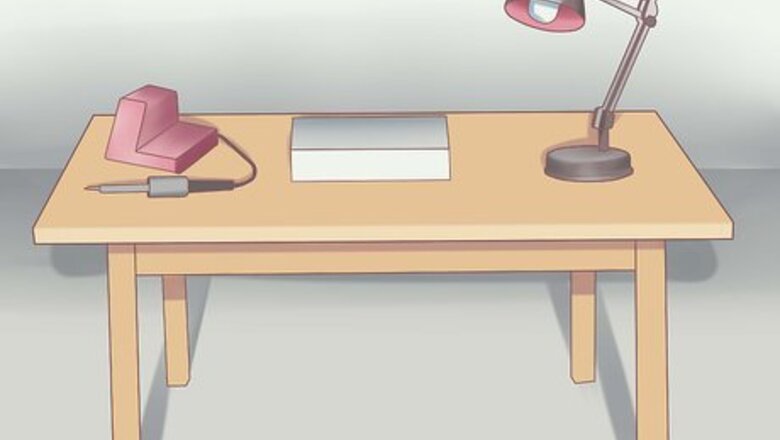

Preparing the Work Area

Find a charcoal soldering block or other appropriate work surface. Soldering will not succeed if too much heat is lost to the air or work surface, so you will need to find a specialized surface with low heat conduction. A charcoal soldering block may be the best option for soldering silver, as it reflects heat to create the high temperature silver requires. A magnesia soldering block or a kiln brick are other common options, and may last through more soldering projects than charcoal. These can be purchased at craft stores or jewelry supply stores, and are similar in size and shape to an ordinary building brick.

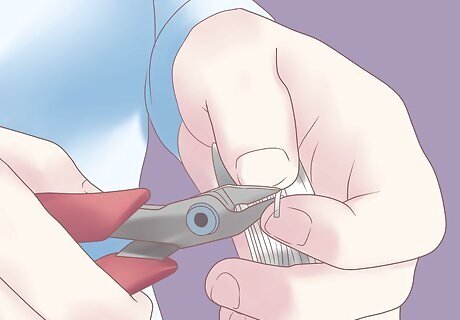

Purchase silver solder. Silver solder is an alloy formed from silver and other metals, designed to join with silver but melt at a lower temperature. You may purchase this as a container of pre-cut chips, or purchase it in sheet or wire form and cut off 1/8 inch (3mm) chips with wire cutters. Do not attempt to use lead solder when soldering silver, as it will usually fail to work and is difficult to remove. Warning: Avoid silver solders containing cadmium, which may cause health problems if fumes are inhaled. If you are filling a crack, you may want to use a lower-purity "easy" silver solder, as it melts at a lower temperature. For joining two pieces together, use "medium" or "hard" silver solder with more silver content, to create a stronger bond. Note that there is no industry-wide definition for these terms; if you are switching brands and want results similar to what you're used to, look at the percentage of silver content instead.

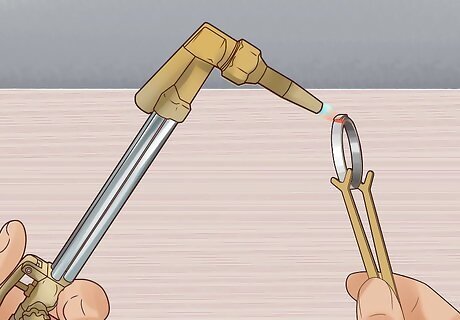

Use a torch, not a soldering iron. Do not use a soldering iron, as these are intended for use with lower temperature lead solder and may ruin precious metals. Purchase a small oxy-acetylene torch instead from the hardware store, preferably with a flat "chisel tip" rather than a pointed one. Silver quickly conducts heat away from the location exposed tot he flame. Because of this, a small torch tip may make the soldering go much more slowly.

Select a general purpose flux or brazing flux. A "flux" is necessary to clean the silver's surface and assist in heat transfer. It also helps remove oxides on the silver's surface, which would interfere with the bond. You may use a general purpose flux, or a "blazing flux" specifically for silver or jewelry. "Brazing" flux is used for high temperature joining, in which the surface of the metal objects themselves are chemically altered. While even jewelers refer to this process as "soldering" instead, "brazing" is technically the correct term. It doesn't matter which form of flux you purchase. (For instance, paste or liquid.)

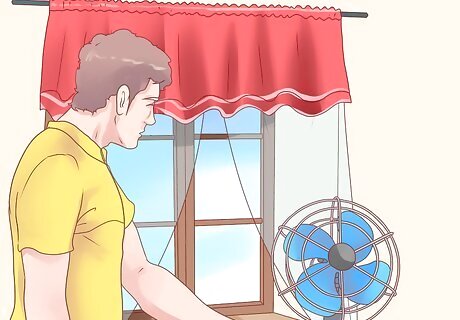

Use a fan for ventilation if necessary. Open the windows or turn on a fan in order to minimize the amount of fumes you inhale, moving the air over the work area and away from you. Keep strong breezes away from the object itself, however, or their cooling effect may make the soldering process difficult.

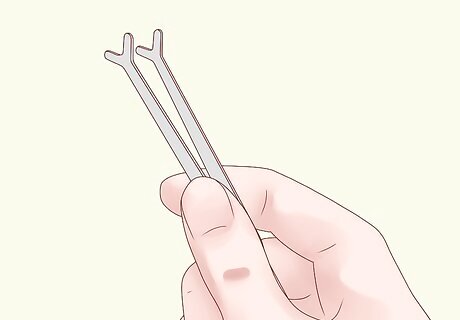

Find tweezers and copper tongs. Copper tongs are recommended, as they can handle high heat and will not corrode and ruin the pickling solution described below. Tweezers are useful for holding the silver objects in place, although these can be made from any metal.

Take precautions with goggles and an apron. Safety goggles are essential to protect your eyes from accidental spatter, since you may need to look closely at the joint. A denim or canvas apron minimizes the chance of burning your clothing. Avoid loose or dangling clothing. Pull back long sleeves and tie back long hair before you begin working.

Set up a container of water. You'll need a container of water to rinse off the silver at the end of the process. Make sure this is deep enough to dip the silver object.

Heat a container of "pickle." Purchase a "pickle," or acidic solution used in soldering, specifically labeled for its suitability for silver. These usually come in powder form. Right before you begin soldering, dissolve the powder in water and use a crock pot or specialized "pickle pot" to heat it according to the manufacturer's instructions. Do not use a crock pot, microwave, or oven that you intend to use again for cooking. The pickle may leave behind a metallic smell or even trace amounts of toxic materials. Never put steel in contact with pickle. Most prepared pickle solutions can keep for several weeks.

Joining the Silver

Clean the silver. A degreasing solution is recommended for oily or heavily handled silver. If there is oxidization on the surface, you may need to place the silver in a pickle solution before soldering. Optionally, you may use 1000 grit sandpaper to make a rougher surface for joining.

Apply flux to the joint. Prepare the flux according to instructions on the packaging, if it is not ready to use. Use a small paintbrush to apply this flux onto the silver object(s). Some people apply flux only where the solder will be present, in order to limit the amount of solder that flows to the wrong place. Others prefer to apply the flux over a larger area to minimize the risk of fire damage, but this is not recommended for beginners. Using a small amount of flux in a separate container is recommended, as repeatedly dipping a brush into the original bottle may add dirt and affect its function.

Position your silver components to be joined. Lay the two components next to each other on the soldering brick. Position them exactly as you want them to be joined, noting that they must be physically touching to be joined properly.

Position the solder onto the joint. Use a pair of tweezers to pick up a solder chip and gently place it on one end of the crack or gap to be joined. Once melted, the solder will be drawn by the heat anywhere flux was applied, so you do not need to cover the entire length of the gap.

Heat the objects until the solder melts. Light your torch and adjust the heat to its highest setting. Begin by holding the torch about 4 inches (10 cm) away from the joint, moving it constantly in small circles to ensure even heating of all components. Slowly move the flame closer to the joint, focusing on the metal objects near the solder, not the solder itself. When the solder reaches its melting point, it will quickly melt and be pulled onto the fluxed areas of the silver. If one of the objects to be joined is thicker than the other, heat the thicker object from the back until the solder starts to melt, then heat the thin object briefly. Use tweezers if necessary to hold the objects in place, but place them on the far end of the silver, away from the flame. You may need to hold down small, thin areas of the silver to provide a heat sink, preventing the thin area from melting.

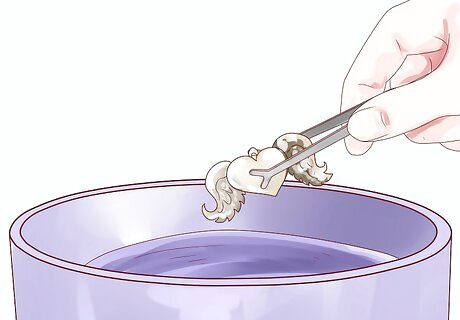

Dip the object in water, then immerse it in a pickle solution. Let the object cool for a minute, then cool it further by dipping it into a water bath. The "pickle" solution described in the work area section is an acidic bath used to clean the jewelry after soldering. Lower the silver into this bath using copper tongs, and leave it for a few minutes to remove the flux and oxidization. Avoid all contact with your skin, clothing, or steel tools, as the pickle bath can be corrosive.

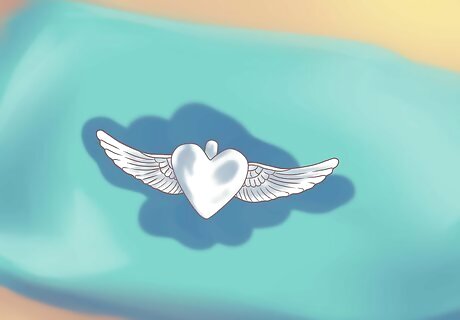

Rinse the silver. Rinse the newly joined silver with water. Pat dry with a clean cloth. If the process was completed correctly, the silver should remain joined permanently.

Comments

0 comment