views

A track bicycle is a type of bicycle (ridden with a single, often fixed gear) that is popular in urban areas for its simplicity, maneuverability, ease of maintenance and its style. In this article the maintenance and disassembly of such a bicycle will be discussed.

For the sake of convenience, this article assumes the bike in question has a fixed gear. This project is best done in a clean space, with a clean floor, as items with grease tend to pick up dirt and debris. This project can be done by anyone with the required tools, a bit of strength (for certain parts) and an interest in bicycle maintenance. This project may take anywhere from an hour to a day to complete, depending on your level of caution and familiarity with the parts.

Pedals

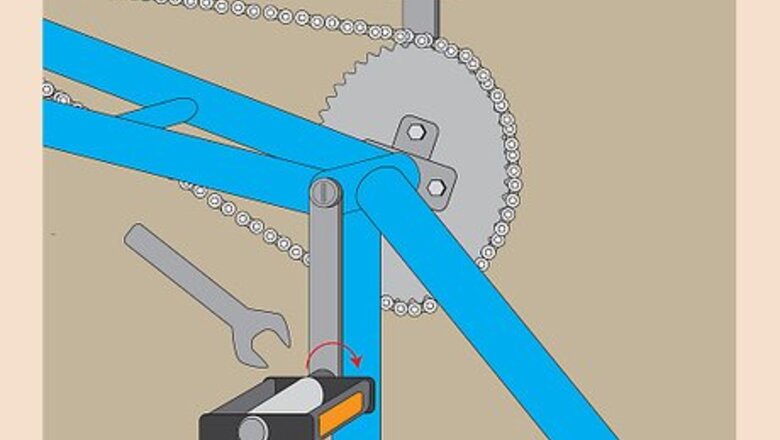

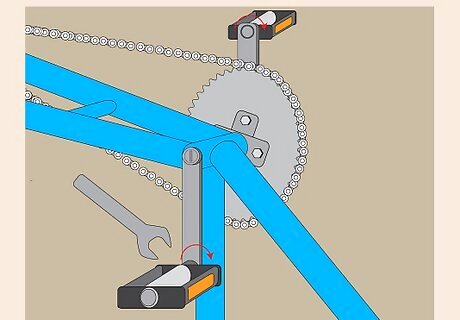

Using the pedal wrench, unscrew the pedal at the edge of the crank arm.

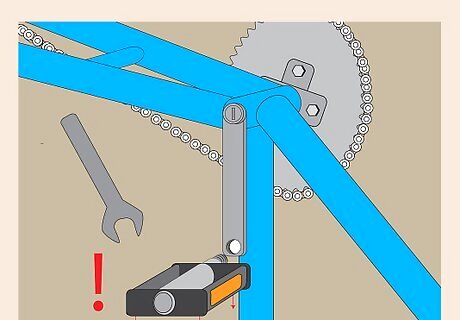

Make sure to hold the pedal up as it gets loose, otherwise it will fall onto the floor.

Left Crank Arm

Remove the dust cap and crank bolt from where the crank connects to the bottom bracket. This usually requires an allen wrench, but may vary depending on your crank brand and type. Once this is removed, there will be exposed threads inside the crank arm, with the bottom bracket spindle visible inside.

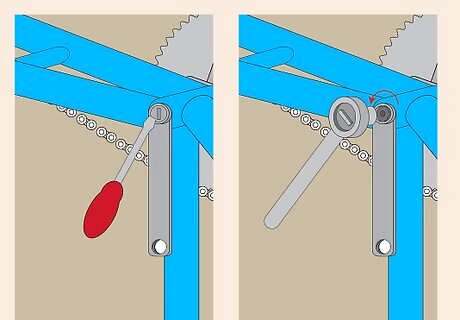

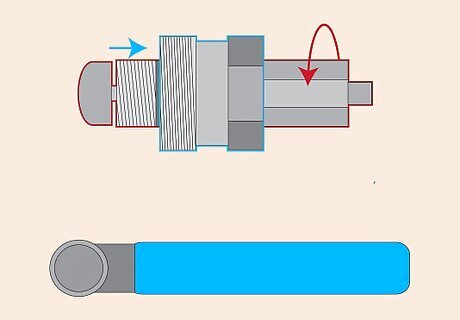

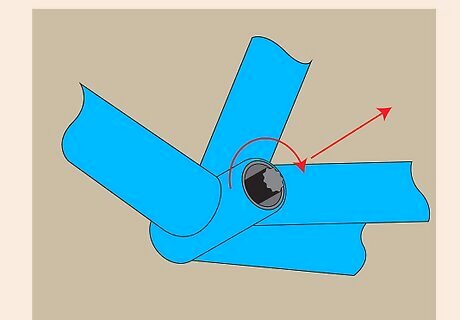

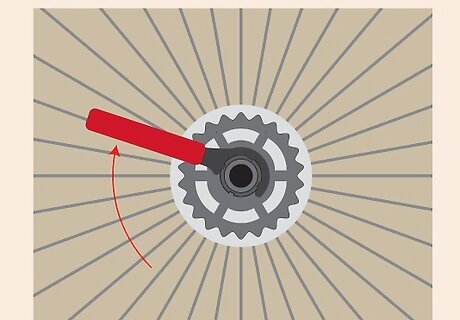

Unscrew the crank puller slightly, until the "pusher" part of the crank puller is recessed within the threaded part of the tool.

Screw the tool into the crank arm, gently at first. Make sure to screw this tool all the way in, as a great deal of pressure will be exerted on the threads when the cranks are removed.

Wind the tool's handle clockwise, screwing the "pusher" part of the tool back into the bolt that is now threaded into the crank. With some force, the crank will be pulled off of the bottom bracket spindle.

Chain

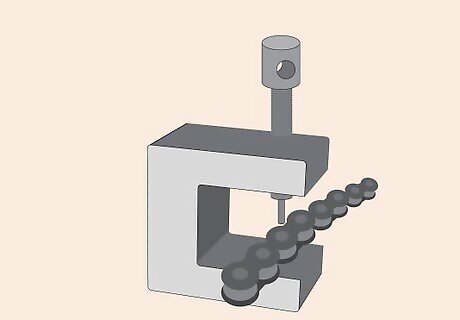

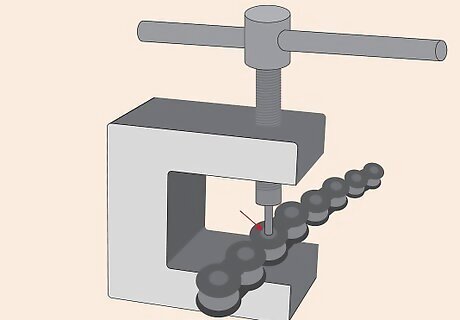

Using the chain breaker tool, pick a link and clip it into the tool. This is done by placing the chain link between the teeth of the chain breaker in such a way that it sits snugly.

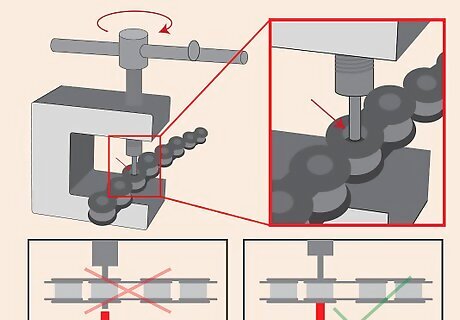

Using the tool like a vise, aim the arm at the small metal piece connecting the chain halves.

Screw in the tool until the metal piece is almost all the way out of the other side. The metal slug that connects the chain link pieces should remain in just one side of the chain link, removed only just enough to let the chain break free. Be careful not to remove the piece entirely! It is extremely difficult to reinsert that piece into a chain. A good way to do this is to alternate between screwing the tool arm into the chain and removing it, checking to see if the chain has broken yet (you won't be able to tell while the chain is in the tool). Go slowly.

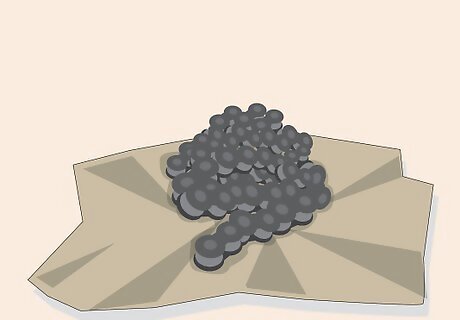

Once the chain is separated, you can remove it entirely from the bike. Make sure to put it on a paper towel or other clean surface, where it will not collect dirt.

Brakes

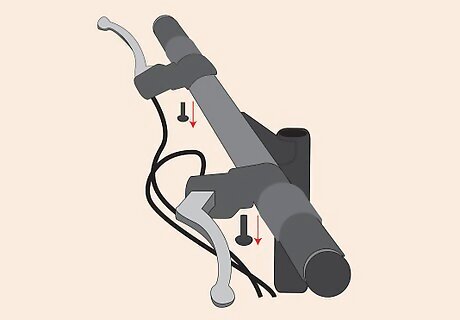

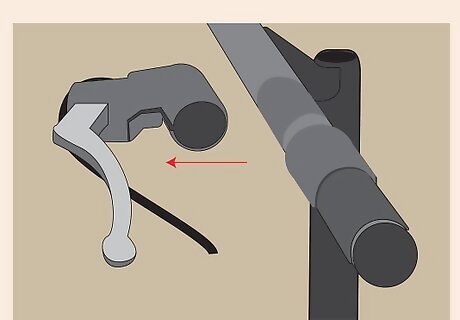

Unscrew the brake lever from the handlebars on the underside of the lever.

Remove the brake lever from the handlebars, making sure to catch any supporting pieces that may fall.

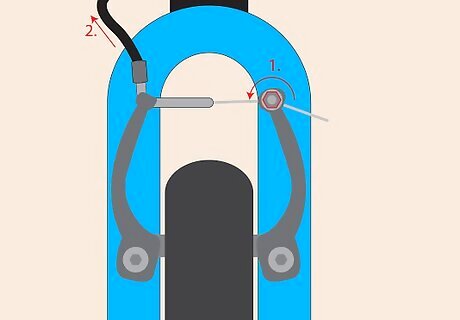

Unscrew the bolt that is driven into the brake through the fork.

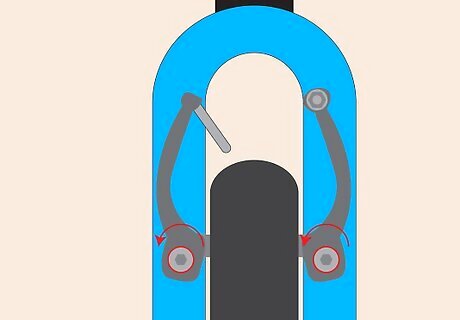

Optional: This is a good opportunity to change your brake pads and clean your brakes. For caliper brakes, unscrew the small bolt on each side of the caliper brake that is attached to the brake pad itself.Take Apart a Track Bicycle Step 15Bullet1.jpg Once the brake pads are removed, unscrew the (smaller) screw on the pad/metal assembly itself, and slide the pad out of the metal piece it is attached to.Take Apart a Track Bicycle Step 15Bullet2.jpg Replace the pad by sliding a fresh one in. This is a worthwhile and inexpensive repair for your bike, since brake pads are cheap and are your best friend on the road.Take Apart a Track Bicycle Step 15Bullet3.jpg

Handlebars

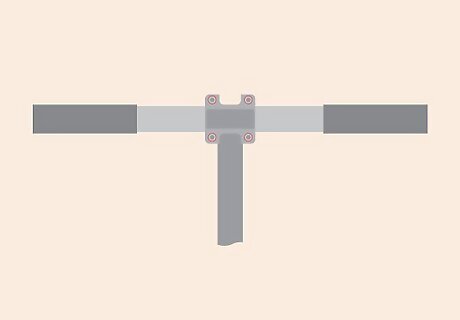

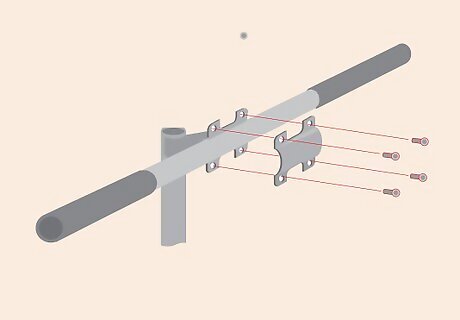

Remove the bolts from the stem that hold the handlebars tight.

Catch the faceplate piece when the last bolt is removed.

Stem

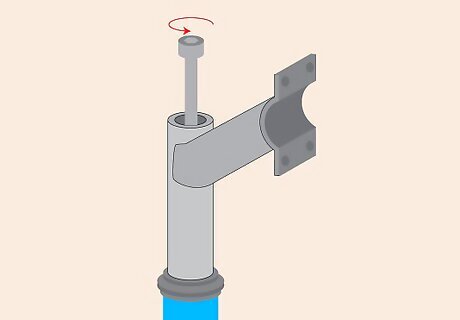

Unscrew the bolt on the cap on the stem.

Unscrew the bolts on the shaft of the stem. (This is the part where the fork can fall out.)

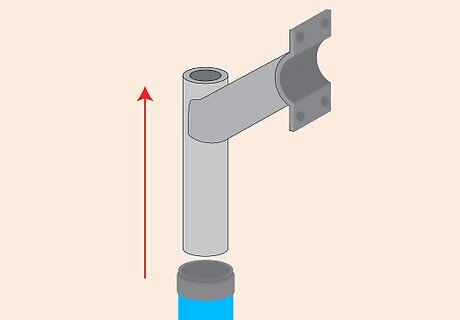

Slide the stem up, off of the fork.

Slide the spacer rings, if any, off of the fork.

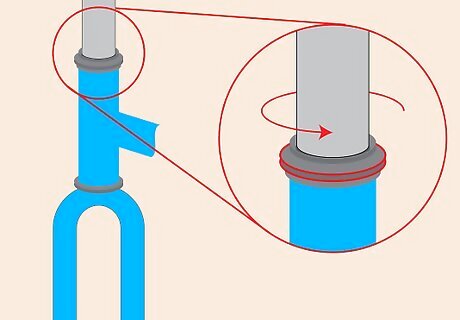

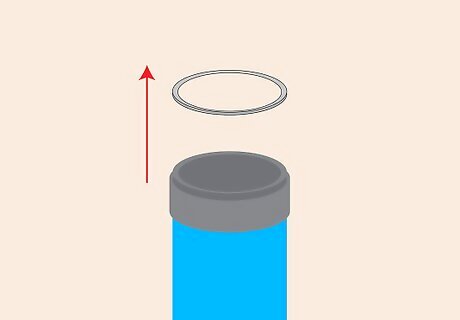

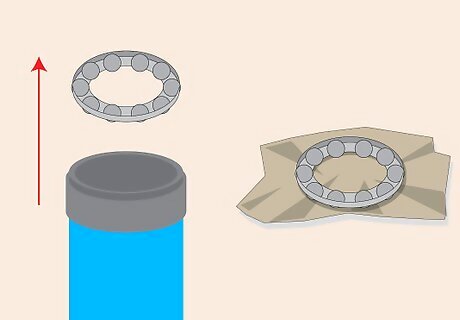

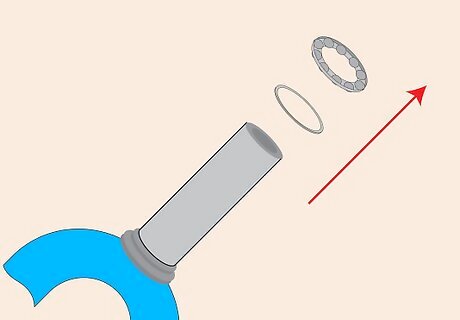

Remove the bearing ring from the cup of the frame. Place this ring on a clean paper towel or other surface. It is a good idea to clean and re-grease this with bearing grease. You can clean the ring by rubbing it with a paper towel in your hands, or with lube/cleaner. Be sure to re-grease this ring liberally; this is what rotates when you turn your handlebars to turn your bike. Ask your LBS (local bike store) for recommendations for bearing grease.

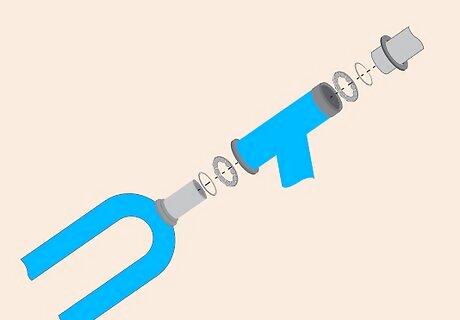

Take careful note of the arrangement and direction of the bearing rings and supporting O-rings at this stage of the project. You will need to replace them exactly as they were.

Fork

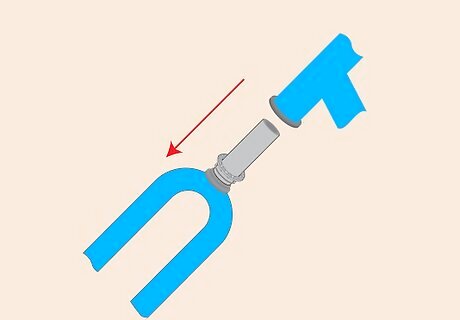

Slide the fork down, out of the frame. Make sure not to lose the bearing ring on the fork that was resting in the lower cup of the frame.

Slide the bearing ring and O-ring up, off the frame.

Bottom Bracket

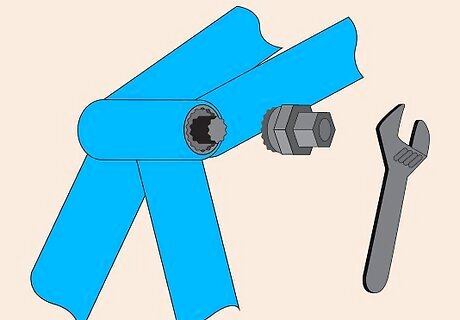

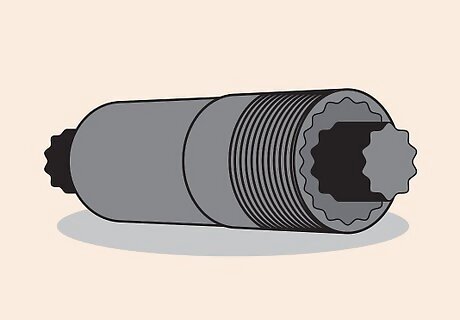

Fit the bottom bracket tool over the bottom bracket spindle. The spindle itself is not very deep; as a result, this tool will easily come out when putting a lot of torque on the wrench to remove the bottom bracket. Be careful not to strip the splines or threads of the bottom bracket.

The ISIS bottom bracket style has two parts, the lock ring cup and the main bottom bracket. These parts are threaded differently, and will require some trial and error to figure out which side the lock ring is on. The lock ring will be threaded normally, and will most likely unscrew somewhat easily (relative to the other side).

Pick a side and turn counter-clockwise until the cup is removed.

Once the cup is removed off of the spindle, turn the frame over and remove the bottom bracket itself, by turning clockwise.

Seat

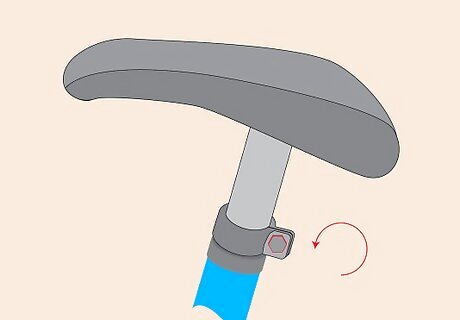

Unscrew the bolt at the top of the frame, where the seat post enters the frame.

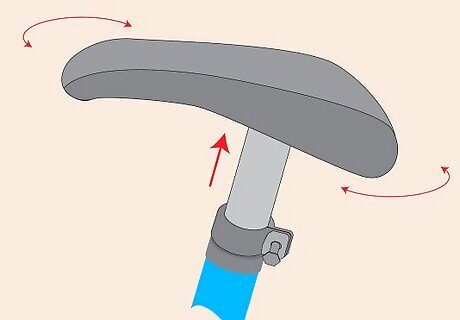

Wiggle and pull the seat and post out of the frame.

Lock ring

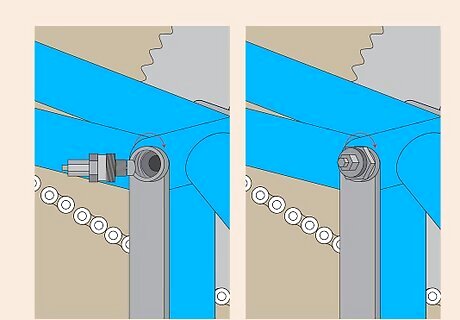

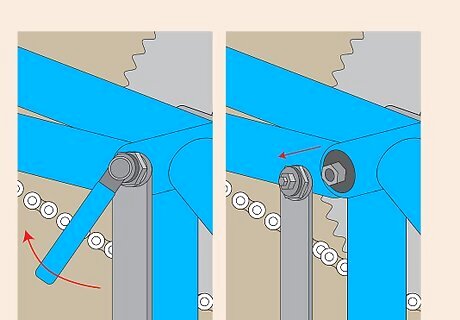

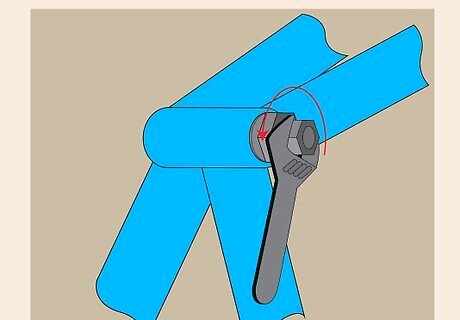

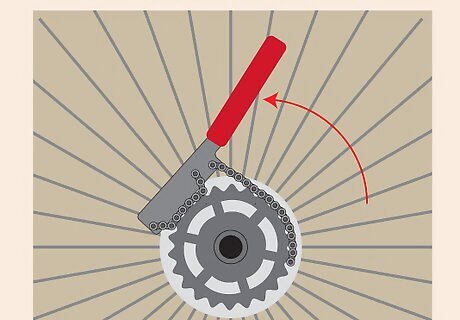

Use the lock ring tool's one-toothed side (if it also has a three-toothed side) to fit into the lock ring.

Turn the lock ring clockwise to remove it.

Cog

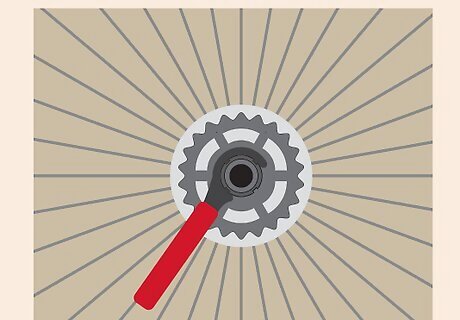

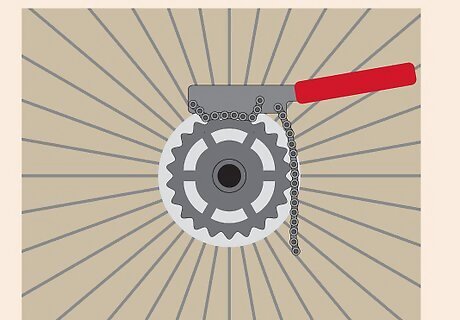

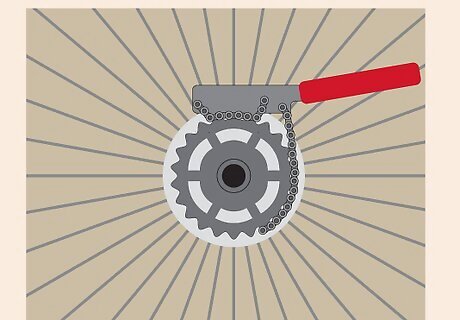

Place the chain whip on the cog, on the chain part of the tool that does not hang loose.

Using your hand, wrap the loose part of the chain whips chain around the cog and apply pressure to the cog directly opposite the other chain.

Hold on tight and turn counter-clockwise to remove. You may have a hard time doing this; get someone else to help or get creative about how to hold the chain onto the cog.

Tires

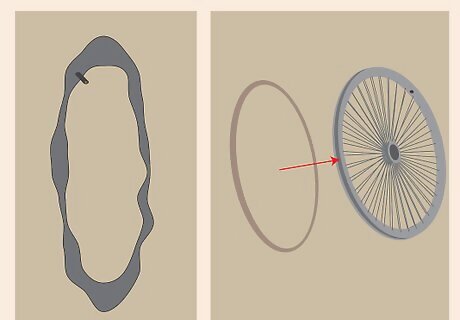

Deflate the tube all of the way.

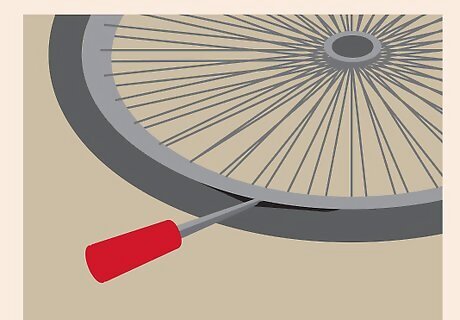

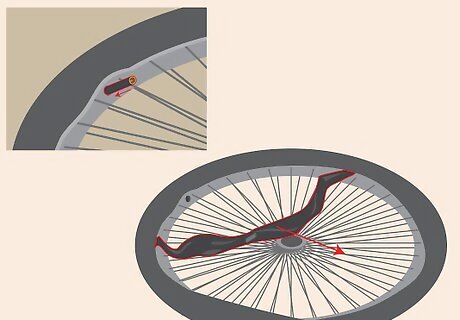

Insert the tire lever under the "clinch" part of the tire, between the rubber tire/tube and the metal rim.

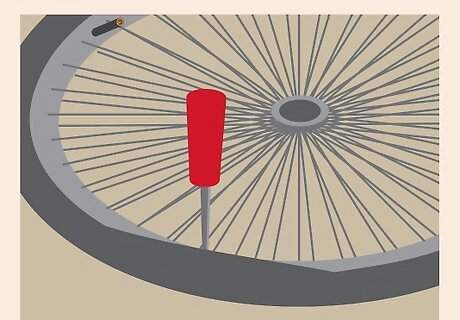

Push up, lifting the lip of the tire off of the rim while simultaneously pushing down the length of the rim.

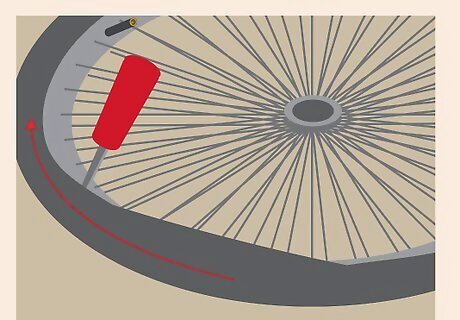

Once a part of the lip of the tire is over the edge of the rim, the rest will come easily.

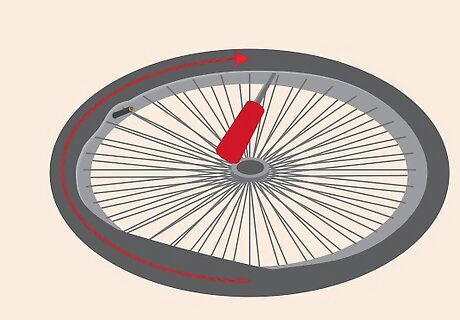

Run the tool down the length of the wheel, removing the lip of the tire as you go.

Pull the valve out of the hole in the rim, and remove the tube from under the tire.

At this point, one lip of the tire will be removed from the rim. Repeat the process for the other side.

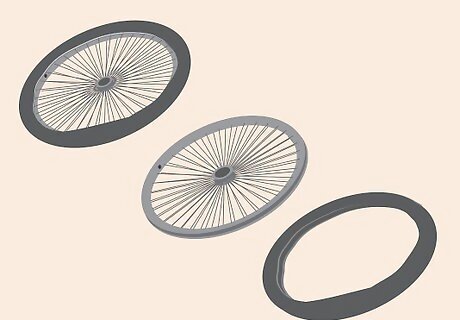

This is a good time to change your tube, or add a rim strip underneath the tube, if you get flat tires too frequently.

Comments

0 comment