views

Choosing the Right Working Space and Varnish

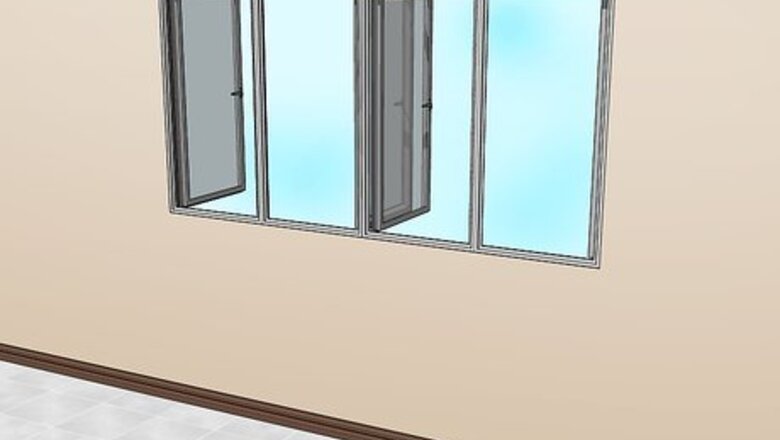

Choose a well-lit, well-ventilated area. Strong, bright lighting will make it easier for you to spot imperfections such as air bubbles, brushstrokes, dents, and bare patches. Having good ventilation is also important as some varnishes and thinners contain strong fumes, which might make you feel lightheaded or nauseous. If the fumes are too strong for you, consider opening a window or turning a fan on.

Choose an area that is free of dust and dirt. The area you will be working in must be very clean and free of dust. You may have to mop or vacuum your work space to prevent dust from settling on your work and ruining it. If you are working outside, avoid windy days, otherwise tiny dust particles may land in the wet varnish and ruin the finished look.

Pay attention to the temperature and humidity. The temperature in the area you will be varnishing should be between 70 °F and 80°F (about 21°C to 26°C). If it is too hot, the varnish will dry too quickly, resulting in tiny air bubbles forming. If it is too cold or humid, the varnish will dry too slowly, thus giving tiny dust particles more time to settle onto the wet varnish.

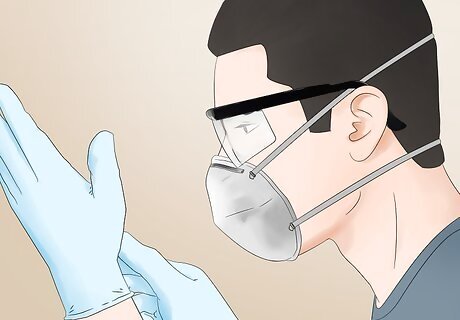

Wear proper protection. When varnishing wood, you will be working with chemicals that may be harmful if they get on your skin; they may also ruin your clothes. Before starting to varnish your wooden piece, consider wearing some clothes that you would not mind getting dirty or stained, as well as some protective gloves and glasses. You may also consider getting a dust mask or a ventilated face mask.

Find the right varnish. There are many different types of varnishes available, each with its own benefits and drawbacks. Some varnishes are easier to use than others, while others are better for certain projects. Choose one that suits your project and preferences. Oil-based varnishes, including some polyurethane varnishes, are very durable. They usually have to be mixed with a paint thinner, such as turpentine. They also have strong fumes and must be used in a well-ventilated area. The brushes you use must also be cleaned well in order to preserve them and make them last longer. Acrylic and water-based vanishes have low-odor and can be mixed with just water. They tend to dry quicker than oil-based varnishes, but they are not as durable as oil-based varnishes. The brushes you use can be cleaned with just soap and water. Spray on varnishes are easy to use. They do not require brushes and they do not need to be thinned. They must be used in a well-ventilated area, however, as they have strong fumes, which might make you feel lightheaded or nauseous. Varnishes are also available in both clear and tinted forms. Clear varnishes will allow the wood's natural color to show through while colored varnishes can act as a stain and tint the piece a specific color.

Preparing Wood for Varnishing

Remove the old finish, if desired. You can apply varnish over an already-painted surface to preserve it, or you can apply it to a raw, unpainted surface. There are various ways to remove old finishes including using paint stripper and sanding. If your wooden furniture has never been painted or varnished, or if you wish to preserve the original paint, then you can proceed to Step 5.

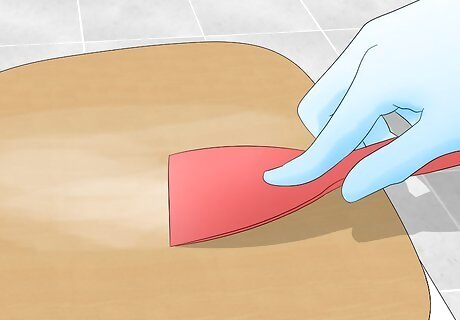

Consider removing old finishes with a paint stripper. Remove old paints and finishes by applying a paint stripping solution to the wood with a paintbrush. Leave the solution on the wood according to the manufacturer's directions, then scrape it off using a putty knife with rounded corners. Do not allow the paint stripper to dry. Be sure to remove any paint stripper residue. How you remove the residue will depend on the type of paint stripper you buy, but most strippers will need to be removed with turpentine or water.

Consider removing old finishes with sanding. You can remove old finishes using sandpaper, a sanding block, or a handheld sander. Sandpaper and sanding blocks work best on uneven or curved surfaces, such as knobs and chair legs. Handheld sanders work best on flat surfaces, such as table tops. Start with a medium-grit sandpaper, such as 150-grit, and move up to a finer grit, such as 180.

Consider removing old finishes with a paint thinner. Much like paint stripper, paint thinner can be used to remove old finishes. Soak an old cloth or rag with some paint thinner, and rub it over the surface of your wooden piece. Once the old finish has been loosened, scrape it off using a putty knife.

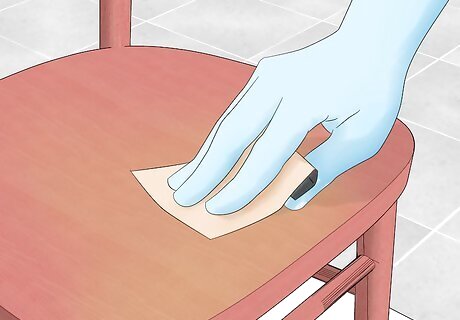

Sand the wood with fine-grit sandpaper. Sanding the wood not only gets rid of any residual gloss or finishes, but it also gives the varnish a rough surface to grip onto. Use 180 to 220-grit sandpaper and sand with the direction of the grain.

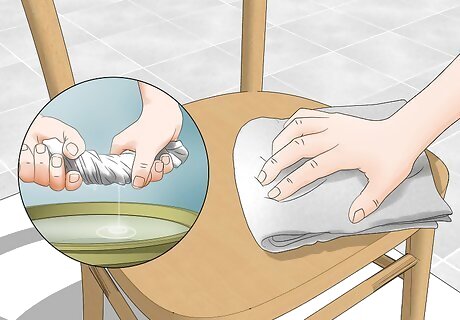

Clean the wood and your work space with a damp cloth and let it dry. Your work space will need to be free of any dust or dirt before you can start applying the varnish. Clean your wood piece by wiping it down with a damp cloth. Be sure to sweep and vacuum the tables and floors of your work space as well; you may have to use a damp cloth or mop.

Consider filling the wood grain. Some open-grained woods, such as oak, need to have the grain filled in with a grain filler for a smooth finish. You can use a color that matches the wood's natural color, or you can use the color of the stain you will be using. You can use a contrasting color to make the grain appear more pronounced, or you can use a similar color to make the grain appear more subdued.

Varnishing the Wood

Prepare the varnish for the initial coat, if necessary. Some varnishes, such as those that come in a spray can, do not need any preparation; other types of varnishes should be thinned for the first coat. This helps seal the wood and prepare it for the proceeding coats. The rest of the coats do not to be thinned. If you are using an oil-based varnish, thin it with a paint thinner, such as turpentine. Use one part varnish to one part thinner. If you are using a water-based or acrylic-based varnish, thin it with water instead. Use one part varnish to one part water.

Apply the first coat of thinned varnish and let it dry. Use a flat paintbrush or foam applicator to apply the varnish to the wood. Use long, even strokes, and work along the wood grain. Let this first coat dry for 24 hours. If you are using a spray on varnish, hold the can 6 to 8 inches (15.2 to 20.3 cm) away from the surface and spray on a light, even coat. Let it dry according to the manufacturer's recommendations.

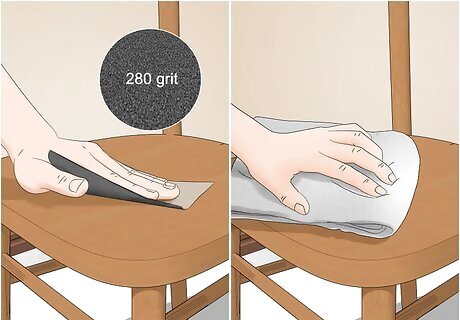

Sand the first coat and wipe it with a damp cloth. After you have applied the initial coat of thinned varnish, you will need to smooth it out. You can do this by buffing the surface of the varnished wood with 280-grit sandpaper, and then using a dry cloth to wipe away any dust of debris. Make sure that you wipe down your work space with a damp cloth to get rid of any dust caused by the sanding. Make sure that you clean your brush with paint thinner (if you are using an oil-based varnish) or water (if you are using a water-based varnish).

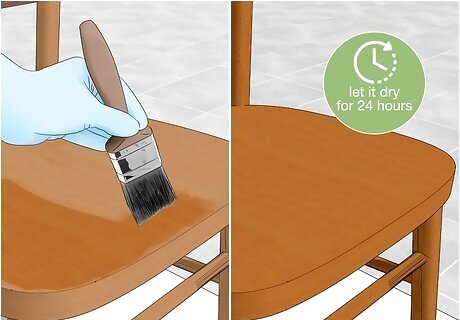

Apply the next coat of varnish and allow it to dry. Using a clean brush or a new foam applicator, apply the varnish to the wooden piece. Once again, make sure that you are brushing along the wood grain. You do not have to thin this layer. Wait 24 hours for this layer to dry. If you are using a spray on varnish, you can spray on another coat. Make sure to keep the can 6 to 8 inches (15.2 to 20.3 cm) away from the surface, and spray on a single, light coat. If you spray the varnish on too thickly, you may end up with puddles, drips, and runs.

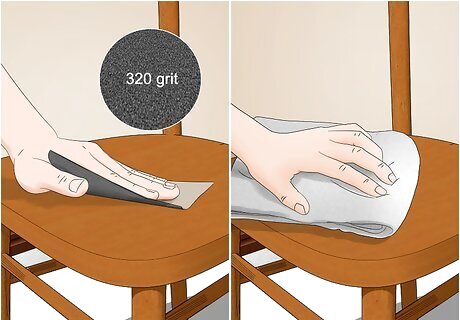

Sand the second coat and wipe it clean with damp cloth. Once the second coat of varnish has dried, sand it gently with a fine-grit sandpaper, such as 320-grit. Let the varnish dry 24 hours before applying the next coat, and remember to clean your work space of any dust or dirt caused by the sanding.

Continue applying more varnish and sanding between coats. Apply 2 to 3 more coats of varnish. Remember to let the varnish dry between coats, and to sand and wipe the varnish clean before applying more varnish. Always work along the grain when applying and sanding the varnish. When you get to the last coat, do not sand it. You can continue working with 320-grit sandpaper, or move up to 400-grit. For optimal results, consider waiting 48 hours before applying the final coat.

Wait for the varnish to finish curing. Varnish will typically need some time to finish curing. To prevent ruining the varnish, leave your wooden piece some place where it will not be disturbed. Some varnishes finish curing with 24 or 48 hours, while others need as much as 5 or 7 days. Some varnishes require 30 days to finish curing. Refer to the instructions on the can for more specific drying and curing times.

Comments

0 comment