views

The following steps are presented in order of least expense and / or level of difficulty to perform or operate, down to most expense and difficulty. Even if properly implemented, none of the steps (except for possibly the last) can be considered "guaranteed to work". If the right combination of low temperature and length of time were to occur, eventually the cold would penetrate the insulation and cool the oil lines.

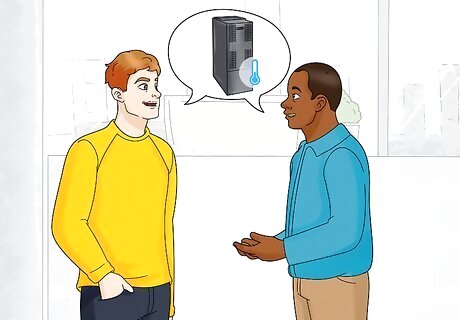

Explain the problem to your oil dealer. He might be able to solve the problem for you. If he can't, you can contact another dealer to hear the solutions they offer. The most common fix consists of a liquid additive that is formulated to reduce or eliminate gelling when added the tank (preferably immediately before refilling). Most dealers offer these additives for sale in 16 oz (or larger) containers; but others provide the additive premixed with the fuel in the delivery vehicle's tank. If you find that you have to solve the problem yourself, be aware that there are many different types of additives available that perform one or more functions. Be sure to select an additive that targets the prevention of gelling or waxing of fuel oils. Read the label and use only as directed.

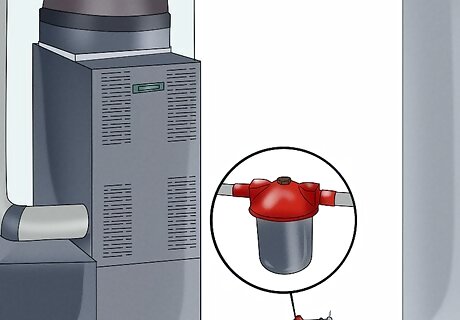

Install the oil filter indoors. The felt filter media of an oil filter can quickly become clogged with wax crystals in winter if located outdoors. Moving the filter indoors will get it into an area that is warmer than the outdoor temperature. Simply install a new filter housing and filter in the indoor location and then remove the filter media from the outdoor filter housing. You can leave the outdoor filter housing in place without a filter.

Wrap fuel lines with insulation that do not absorb moisture. Minimize the amount of pipe exposed to the cold temperatures by completely insulating or moving them indoors when possible. Carefully seal all openings and seams in the insulation to prevent exposure to cold temperatures.

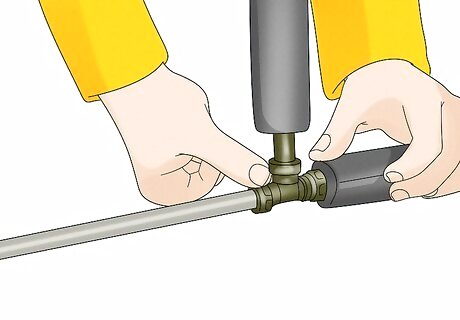

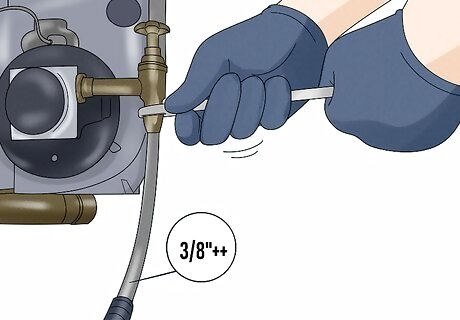

Install larger fuel lines. Because it will take longer for larger diameter fuel lines to become clogged completely, a fuel line with a diameter that is larger than the standard 3/8" type will allow oil to flow for a longer period of time when compared to smaller diameter lines. Sometimes, this additional time is long enough to "ride out" a period of extreme cold.

Add K-1 (kerosene) to the home heating fuel tank. This will mix with fuel oil and lower the "freeze" point, as the freeze point for K-1 is about -20F. K-1 will burn successfully in just about any home heating fuel oil furnace, but the downside is the expense (historically, K-1 can cost a 20% to 30% higher than fuel oil).

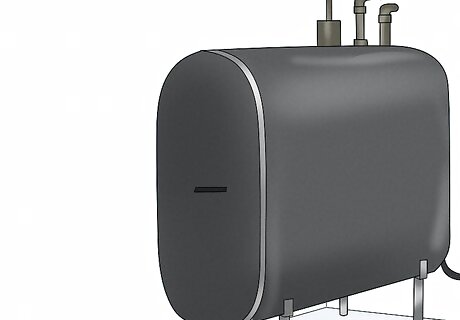

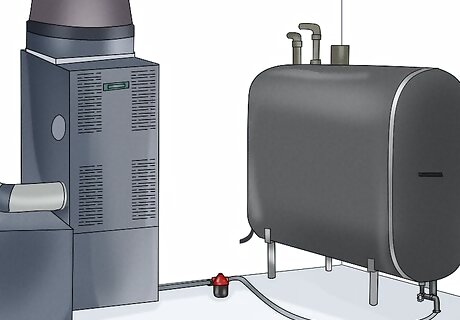

Install an electric fuel oil tank heater. Install as directed by manufacturer (use a search engine to find a current list of "fuel oil tank heater" suppliers). Sheet type heaters and drum heaters may also be customized for use on the exterior of tanks. These will work best when installed on the bottom or lower sides of the tank and are secured with RTV adhesive (as opposed to straps and clamps). Installing on the bottom of the tank helps distribute the heat because heat rises. This rising heated oil will thermally "stir" the contents of the tank. Make sure the heater selected is appropriate for the location of the tank (such as wet or outdoor). The cost of operating this heater will be reflected in your electric bill and because of this, it should be a "last resort" type fix. These heat sheet products are available at industrial supply stores

Build a room around the tank. While this is the most expensive solution, it will nearly always work. Add a small heat source, or if connected to the home, provide a small amount of airflow between the room and the rest of the home to prevent gelling of the fuel.

Comments

0 comment