views

Locate the area of wire in need of repair. If removing the area would make your wire too short, consider adding addition cable to lengthen it. In some cases, it may make more sense to just buy a new cable.

Clean it up. If the wire has an area that is mangled, cut that area out.

Determine which splicing technique you will use for splicing the small (usually 22-28 AWG) wires together. Use a technique that you feel comfortable using. As long as there is continuity through your splice, it should work.

Place a long piece of larger shrink tube on one side of the split. This shrink tube can very in length, but usually between 2-6 inches will be appropriate. The length will depend on your splicing method.

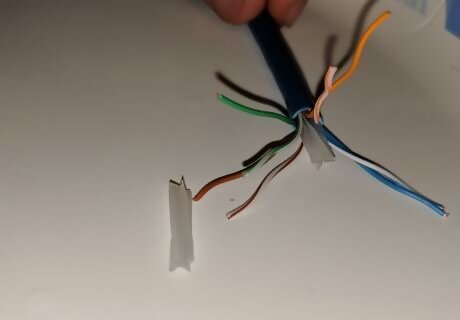

Take your preferred cable strippers and cut an area of insulation that is an appropriate length for your splicing technique, from both of the cables. If there is a metal film underneath this area, you may remove this. Do not cut or nick the 8 smaller wires located beneath the insulation.

Spread your 8 wires apart. If your wires have a cotton or cloth-like material between them, you may remove this as well. It is there as a padding for the wires.

For each of the wires, place a piece of shrink tube, measuring approximately 3 times the length of your splice, on one side of the cut. The shrink tube should be large enough to go over the splice you are about to perform, but not so large that it will not shrink down to the wire gauge you are using.

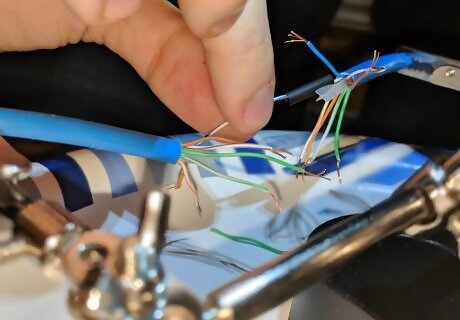

Using a pair of wire strippers, remove the length of wire appropriate for your splicing technique from each of the 8 wires. Perform this step on both cables (you should strip 16 wires total.)

Perform a splice on each wire. You will splice the orange wire from one side of the cable to the orange wire from the other side of the cable; the orange/white wire from one side of the cable to the orange/white wire from the other side of the cable; and continue this pattern with all 8 wire colors. Avoid adding a lot of solder, as it will make the wires brittle and may cause another failure later on.

Use a multimeter to measure the resistance along each of the wires within the ethernet. To do so, place a lead at each end of the wire on the same wire. If the resistance reads higher than 3 ohms for a cable less than 100 feet, you should attempt to redo your splice. If you read an open (O.L. on most ohmmeters), make sure the correct wires are spliced together. If you have verified that you are using the correct wire and still show an open wire, you may have a bad wire and may want to replace the Ethernet cable.

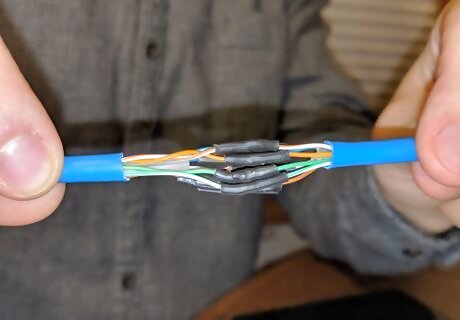

Move the smaller heat shrink tube over each of the 8 splices. The shrink tube should be centered over the splice, with the ends extending over the insulation on both sides. Using a heat gun, shrink the tubes completely. When they are completely shrunk, you should not be able to move them along the wire any longer.

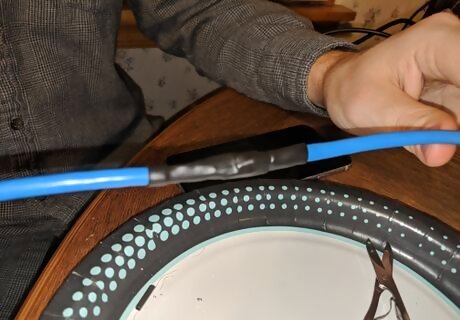

Place the larger heat shrink over all 8 wires. The shrink tube should be centered over all 8 wires and with both ends extending over the insulation of the cables. Heat the shrink tube completely over the wires.

Test out your Ethernet! You may plug each end into a tester or attempt to use the cable as a network cable to verify its operation. If it works, you have successfully repaired your Ethernet cable.

Comments

0 comment