views

Listening for Bad Fuel Injectors

Put on the appropriate safety gear. Before beginning any automotive project, you need to take steps to protect yourself from injury. Eye protection like safety glasses or goggles will keep debris from falling or spraying into your eyes while you work. Choose eye protection that fits comfortably and won't interfere with your vision. Gloves are an optional addition to the safety gear required for this task. Gloves can protect your hands from sharp objects or pinches while working in the engine bay. Eye protection is required for this project.

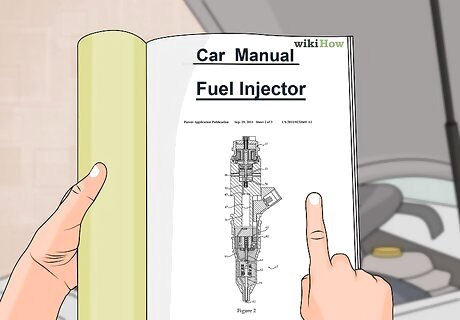

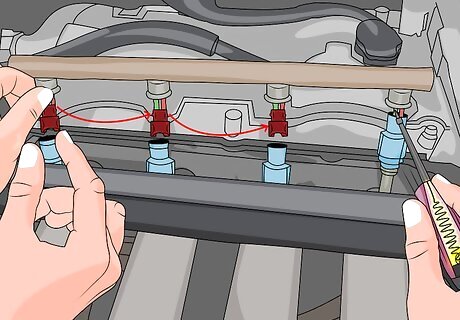

Open the hood and locate your fuel injectors. The easiest way to locate the fuel injectors for your specific vehicle is to refer to the service manual for that vehicle. Most applications have one fuel injector for each cylinder. They are usually located on the intake manifold and are connected to one another with a fuel rail. The fuel rail is a cylindrical rail that will run along the top of the intake manifold, and each fuel injector will be between the fuel rail and the intake manifold. V style engines (V6, V8, V10) will have two fuel rails with half of the injectors on each side of the motor.

Find a long metal rod or screwdriver. Locate a thin piece of metal that’s at least a foot or so long. It should be made mostly of metal, but you could opt to use a screwdriver despite it having a plastic or rubber handle. Make sure the piece you choose is at least a foot long, but not more than two feet. A long screwdriver or thin piece of rebar will work fine.

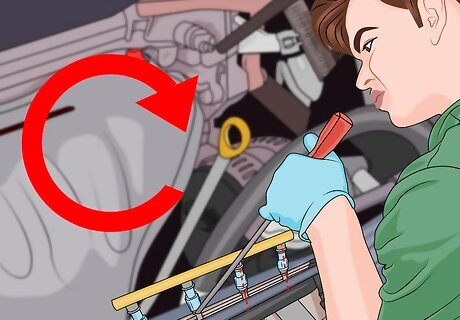

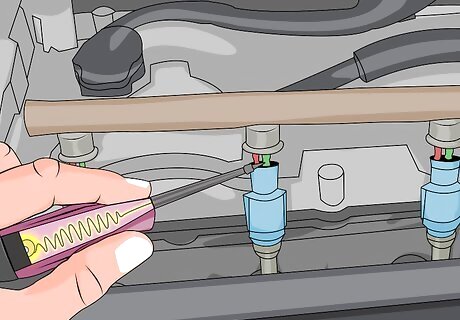

Place the tip of the rod on a fuel injector. You will be using the metal rod to transmit sound from the fuel injector to your ear without having to bring your face too close to a running engine. Set one end of the rod or screwdriver on the injector itself while holding it up with one hand. Make sure to hold the screwdriver or metal rod at an angle that will allow you to bring your ear to it.

Bring your ear close to the rod and listen for clicking. Lean your ear close to the end of the metal rod or screwdriver that is opposite the injector. As the engine runs, listen for an audible clicking sound given off by the injector. This sound indicates the injector being activated. Be extremely careful leaning your head into the engine bay, and ensure you keep your eyes open as you listen to the rod to prevent accidentally getting injured. If you have long hair, tie it back tightly to prevent it from getting caught in any moving parts under the hood.

Repeat these steps for each injector. Use the same method to check each fuel injector in your vehicle. If you find one that is not clicking, there is an issue with the injector or the electronic control that is transmitting to the injector. If you have an OBDII scanner and your vehicle’s check engine light is on, you can check to see if there have been any errors in the vehicle’s computer regarding that cylinder or injector. Replacing this injector may solve the problem, but you may also need to have a diagnostic done of your vehicle’s electronic control unit and fuel system by a professional mechanic.

Ensuring the Injectors Are Receiving Power

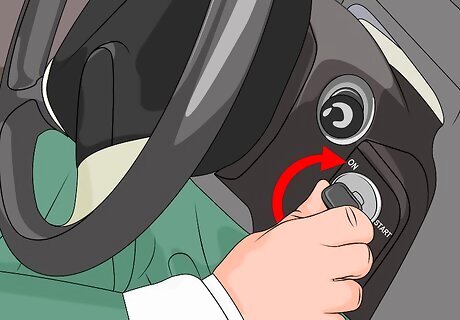

Turn the key to the “on” position without starting the engine. To conduct this test, the vehicle's electrical system must be active without the engine actually running. Insert the key and turn it until the electrical system activates, but stop before you engage the engine's starter. This should activate all of the vehicle’s electronics like interior lighting and the radio. If you accidentally start the vehicle, simply turn it off and try again. The vehicle’s battery is powering everything during this test, so you should turn off things like the headlights and stereo to conserve power and ensure it has enough to start the vehicle again later.

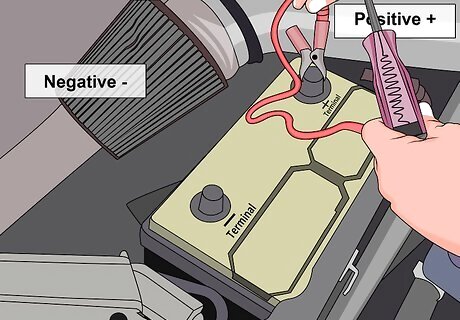

Connect a test light to the negative terminal on the battery. A test light looks like a screwdriver with a finely pointed end and a wire hanging out of the handle. When the wire from the handle and the pointed end come into contact with a completed and powered circuit, a lightbulb lights up inside the handle of the test light. The wire extending from the handle will have an alligator clip at the end. Attach that alligator clip to the negative terminal of the vehicle’s battery. You can identify the negative terminal on the battery by looking for the negative symbol (-) or the letters NEG. Make sure the clip has a good metal on metal connection to make the test light work.

Locate the two wires going into each injector. Each fuel injector will have a metal clip plugged into it with two wires coming out of it. One of those two wires is a 12-volt constant that should be continuously receiving power from your vehicle’s electrical system. There should be a small portion of each wire exposed coming out of the plastic clip that connects to the injector. These wires are often grey and black, but can come in any number of colors. They will be the only wires coming from each injector.

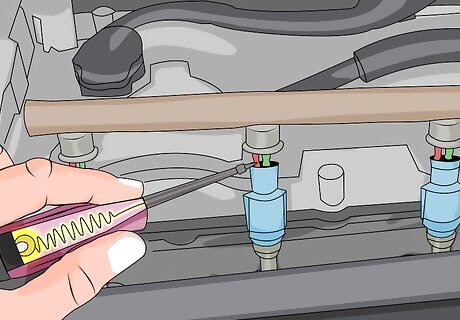

Test each wire for voltage. Take the sharp end of the test light and press it firmly into the rubber coating around each wire until it penetrates into the metal wiring itself. One of the two wires should make the test light turn on when it comes into contact with the wire inside the protective coating. If the test light turns on with one wire, then the injector is receiving the necessary constant voltage. Make sure to wrap a piece of electric tape around any holes in the wiring’s protective coating that are big enough to see. If neither wire makes the light turn on, then there is an issue with the power reaching the fuel injector, which will result in in failing to fire. If the all of the wires that light up are a certain color, make note of which wires are the constants.

Repeat the process for each injector. Test each wire coming out of the fuel injectors in your vehicle. If you locate one injector with a power issue, that doesn’t mean others may not have the same problem. Once you identify an injector with a power issue, make a note of which one it was and continue to test the rest. Follow the wires on the injectors that fail to engage the test light to make sure there are no breaks in the wire that may prevent the electricity from reaching it. Let your mechanic know that you were able to identify the injector with a power issue. It may require replacing the vehicle’s electronic control unit.

Checking the Trigger Circuit for the Injectors

Connect a test light to the positive terminal of the battery. Take the same test light that you used for the previous test, but this time connect the alligator clip to the positive terminal on the battery instead of the negative. You can identify the positive terminal by looking for the positive sign (+) on the battery or the letters POS. Make sure the alligator clip has secure, metal on metal contact or the test light will fail to function.

Have a friend start or turnover the engine. Have a friend start the engine. If the vehicle won’t currently run, have your friend attempt to turn it over as you test each injector. Make sure you do not have any clothing or body parts hanging into the engine bay as it starts or turns over. If the engine won’t start, remember that attempting to turn it over for too long can kill the battery and damage the starter. Only attempt to turn it over with the test light in place.

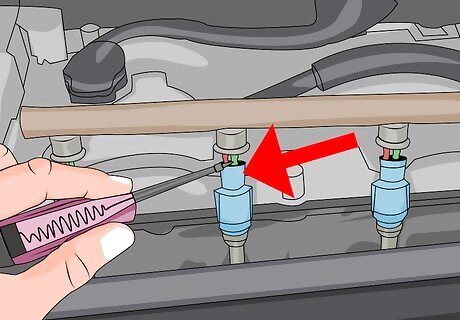

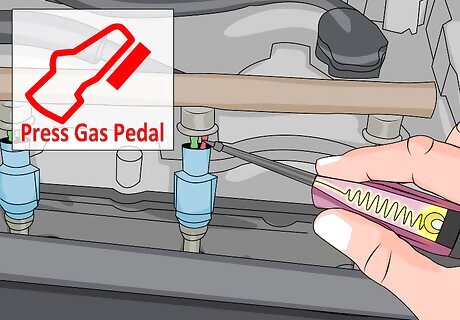

Probe the opposite wire with the test light. Use the test light and check the opposite wire of the constants you identified in the previous test. Press the sharp end of the probe through the rubber coating firmly until it makes contact with the metal wire inside. Be careful not to press the probe all the way through the wire and out the other side. Always cover holes in the wire’s protective coating with electric tape once you’re done.

Look for flashing or flickering light. With the engine running at an idle, the test light should flicker dimly and as your helper applies throttle by pressing the gas pedal, the light should flicker more brightly. This light represents the signal being transmitted by the ECU to the injector to spray fuel. If the test light is failing to light up, the injector may be bad or there could be an issue with the electronic control unit for the vehicle. This issue could be caused by a failing ECU, or one of the injectors along the fuel rail may be faulty. The electrical pulse is transmitted through each of the injectors to one another, so one faulty injector could cause issues in multiple injectors.

Disconnect the wiring clips to each injector and begin the test again. With none of the injectors connected, the flickering pulse should transmit through all of the wires without any issue. Use the test light to confirm this on the wire for the last fuel injector clip (at the end of the fuel rail). Keep the test light connected as you reconnect each fuel injector one by one. As you connect each injector, the pulse intensity should remain the same. It shouldn’t change until you connect a faulty injector that creates too much resistance for the pulse to travel through easily. When the pulsing light dims as you connect one of the injectors, that injector is faulty and needs to be replaced. You can purchase new fuel injectors for your vehicle at most auto parts stores.

Comments

0 comment